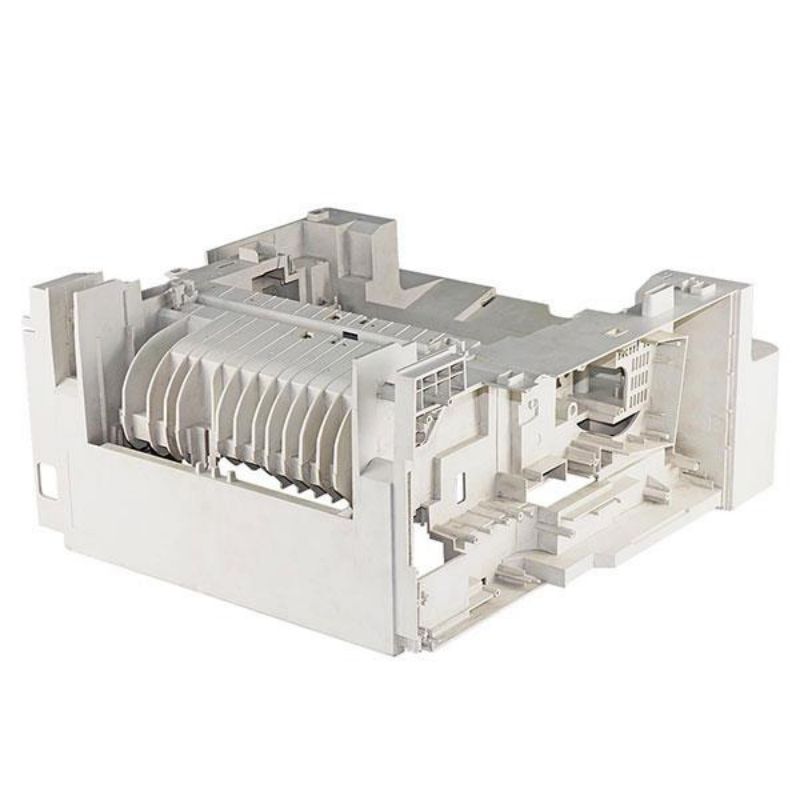

Plastic Injection Mold for OEM Laser jet Toner Cartridge Components Printer Plastic Accessories

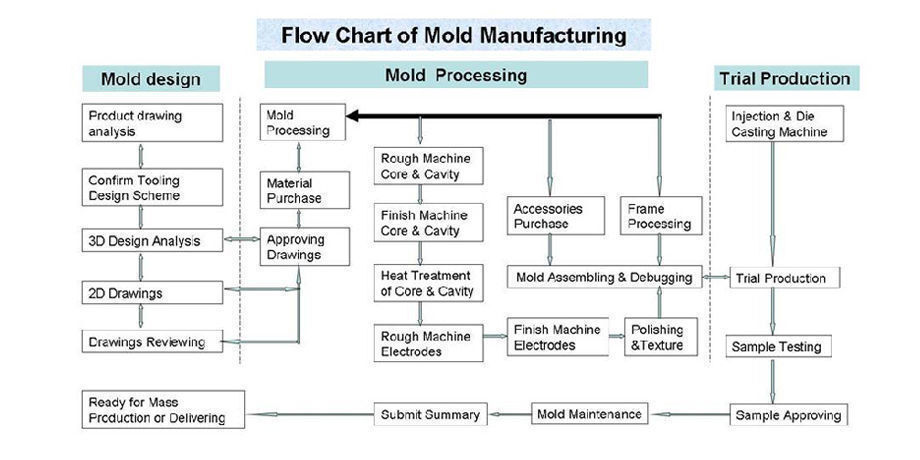

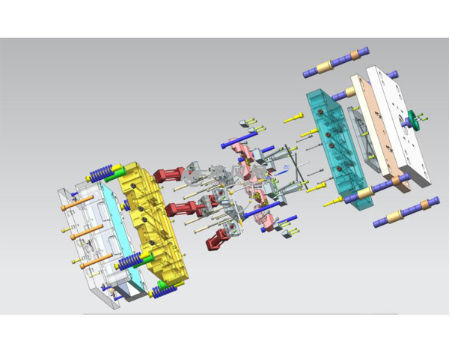

Complete end-to-end solution from mold design

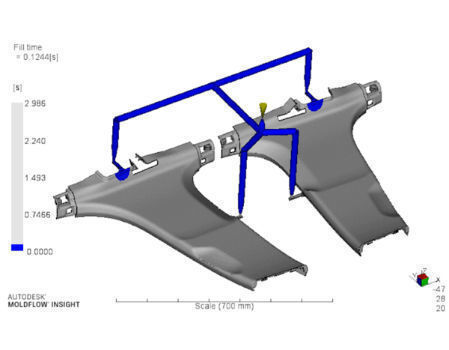

Mold flow analysis, DFM, VAVE, FMEA

Multi-cavitation mold fabrication

Testing and commission for mass production of Plastic injection molding

Products

Products DETAILS

Plastic Injection Mold for OEM Laser jet Toner Cartridge Components Printer Plastic Accessories

Dedasun is a professional manufacturer in Plastic Injection Mold for Original Laserjet Toner Cartridge Componments Printer Plastic Accessories

-------------------------------------------------------------------------------------------------------------------------

Key Specifications/ Special Features:

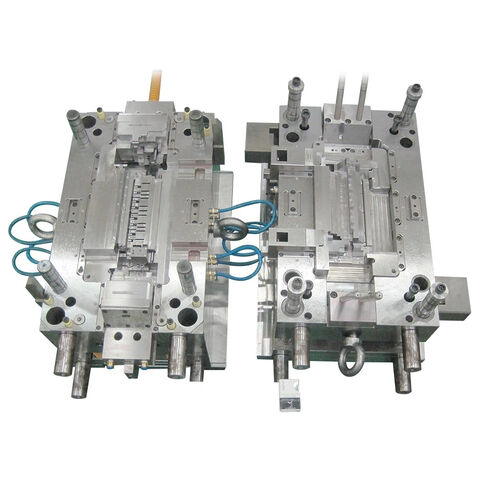

Technical Specification & Features Core / Cavity : P20, 718, NAK80, S136, SKD61, S7 ,SKD11, 1.2738, 1.2311, 718, or customized

Raw Plastic materials: PEEK,PP, PE, ABS, PC, Acrylic, PS, POM,PA/ABS alloy ,PA+GF ,PVDF ,PBT, PA6,PA66,TPE or customized

Material Brand : BASF, Ticona, EMS, Exxonmobil, Bayer, Dupon, SABIC, Rhodia etc

Runner Designs : Cold Runner & Hot Runner Injection Gate : side, submarine, pinpoint, sprue, tunnel gate and or customized

Hardness ( HRC ) : Vacuum heat treatment

Mold Base : LKM ,DME & HASCO

Mold Attached : assemble limited switches , eye bolts, springs, nipples, O-ring, ejection pins

Design software : VISI, SolidWorks, Pro-E, 3D Max, AutoCAD and UG

Processing Machines : Precision grinder ,CNC, high-speed engrave, EDM, WEDM

Tool life : depends on customer's requirement . 500,000 shots at least Customized designs are accepted Small Orders are available OEM/ODM orders are welcome

-------------------------------------------------------------------------------------------------------------------------

Our advantages:

[Technical team]

Our company has a strong technical team which has long time working and production experience, design molds with 3D nano tiny texture in nano embossing technology.

[Custom moulds]

According to clients' demand, we customize texture mold , merge texture, window, logo, button into one, and complete all work flows with high efficiency in a short time.

[ Technological innovation]

In PET,PC,PMMA,glass and other non-metallic materials surface to make metal color and texture.

Printer Plastic Accessories Plastic Injection Mold for Original Laserjet Toner Cartridge Componments

- Our equipment :

Equipment for mold tooling:

- CNC machines: 30 sets

- Electric discharge machine : 15sets

- Wire cutting machines/ slow-feeding NC wire-cut machine: 8 sets

- Milling machines, plain grinding machines. drilling machines : 15 sets

- Equipment for injection molding:

- Injection machines : 15sets (100Tons~1500Tons)

- Double injection machines: 3Sets

- Measurement equipment: 100 sets

- 3D coordinate measuring machine 2set

- 2D projector 1set

- Our capacity:

- Over 20 sets molds per month. Standard: HASCO. DME, LKM, Non-standard

- Monthly production of plastic products 400,000~600,000 pieces. Including post processing: painting spray, printing, e-plating.

- Monthly production of machined metal part 100,000~200,000Pieces.Including aluminum & zinc die cast, steel machining , stamping.

Payment terms:

Mold charge: 50%~70% deposit on start mold tooling,the balance is paid off when mold is accepted for production .

payment for goods: 50%~70% deposit on order,the balance is paid off when the goods is ready for delivery.

Shipping and Business Terms:

Time for mold tooling:25~40 workdays (depends on the product design)

Lead time for product delivery:7-15 workdays (depends on the volume of order and post processing)

Sample is possible.The sample price and freight is determinded by the actual cost.

FOB Shenzhen, China.

We have our mold workshop, with full range of machines for mould making: 30 CNC, 15 EDM, 8 wire-cut,

and 15 other machines and equipment , with 25 technical workers.

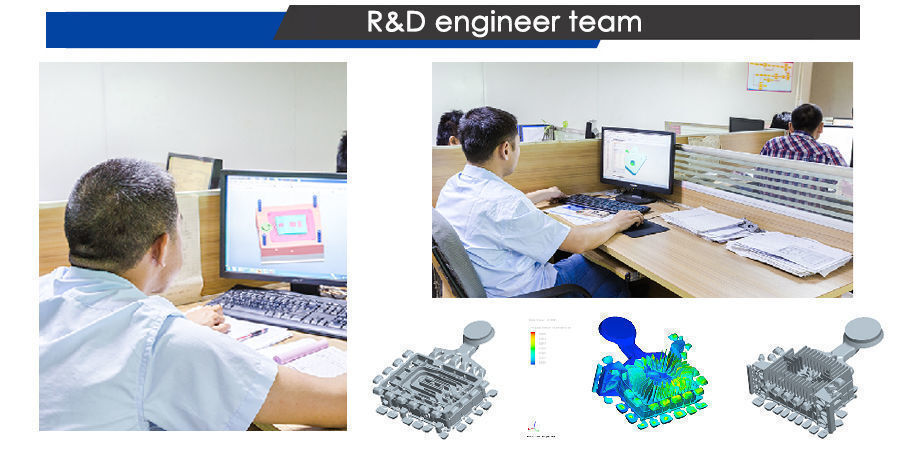

We have our R&D engineer team with 10 engineers of 6~10 years’ professional experiences in die casting products design and mold design. We use CAD, UG and Flow-3D, as well as mold flow simulation analysis software, the company ensures high efficiency and effectiveness, and risk reduction in the process of design.

We offer our customers with plastic mold design, manufacturing and plastic products for following fields:

1.Electronic products housing / enclosure

2.Medical device , tool, equipment housing / enclosure

3.Stereo and digital product

4.Electrical and industrial equipment

5.Home appliances

6.Automotive peripheral electronic products

7.Computer peripheral products

8.Mobile peripheral products

Q&A

How to get a quick and accurate quotation?

The design and function of products and the orders volume determine the product process, early investment and unit price of products. In order to quickly and accurately evaluate and obtain the quotation, the customer is required to provide the following product data:

1. Product parts list: list the parts, dosage, materials and surface treatment contained in the product.

2. Product design drawings: 3D drawings, STP and IGS format documents.

3.2d drawing, specifying product dimensional accuracy requirements and local processing requirements.

4. Product surface printing and coating documents

5. Prediction of die life and order quantity.

6. Requirements for subcontracting and transportation of products.