Precision CNC Machining Spare Part for Machinery Industry Use

Why do Industrail Equipment Manufacturer Choose us? We have been in the manufacturing industry for many years and are familiar with the technical principles of all kinds of industrial equipment. We can provide you with professional manufacturing technical services, including CNC machining, injection molding, sheet metal etc., to provide you with the best market competitiveness for your equipment.

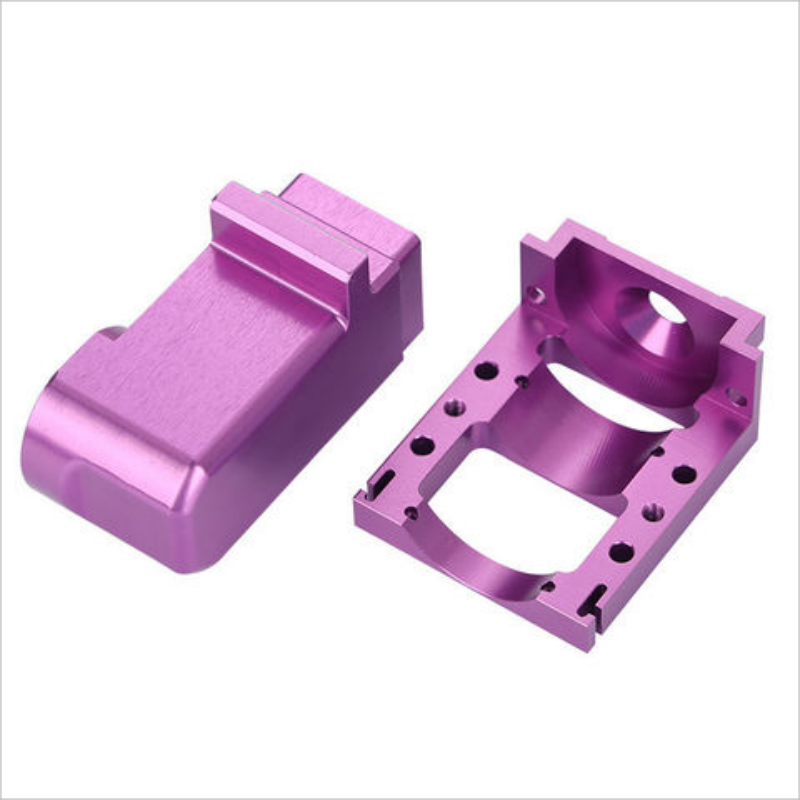

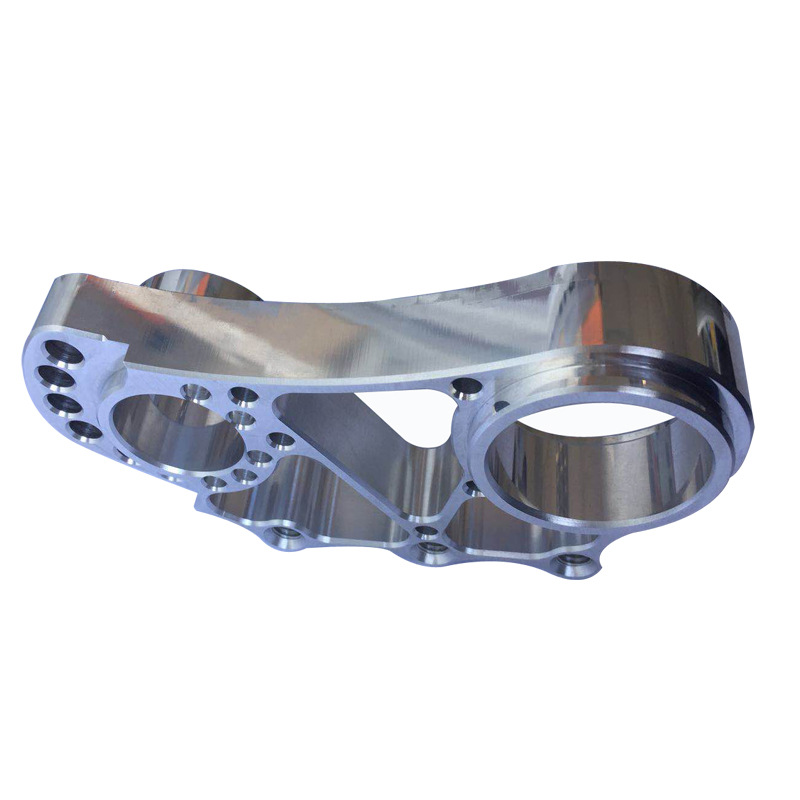

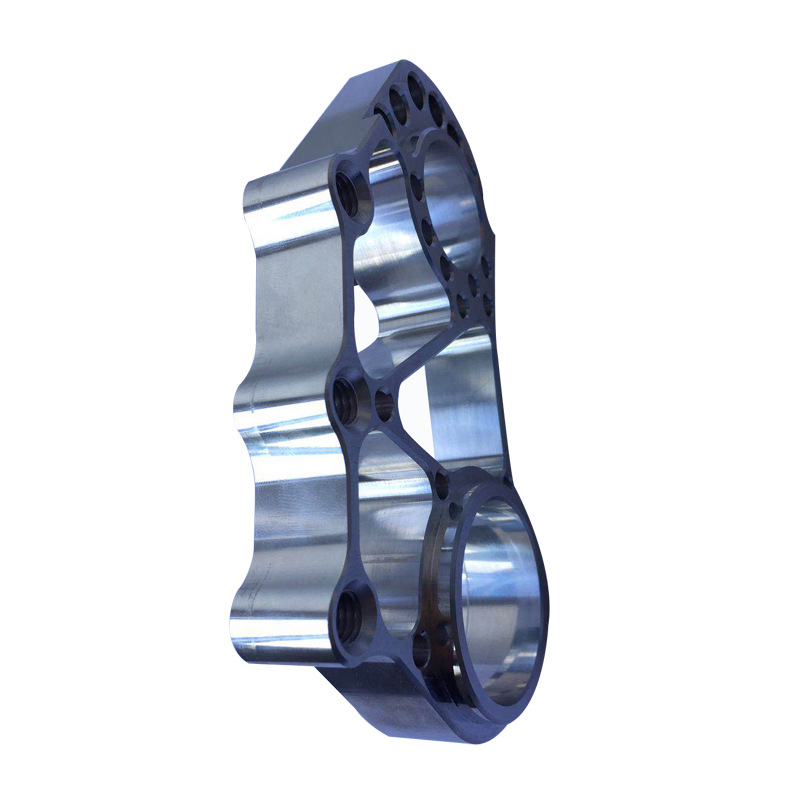

Products

Products DETAILS

Precision CNC Machining Spare Part for Machinery Industry Use

Which Industry Equipments are Served by us?

We can provide specialized services to manufacturers of engine parts, transmission parts, and related components to help them improve the quality of their products. Our extensive expertise in manufacturing processes helps us meet the needs of each unique customer.

This is the highest strength alloy of the more non-heat-treatable grades. Its fatigue strength is higher than most other aluminum grades. It has good resistance to the marine atmosphere and saltwater corrosion and excellent workability.

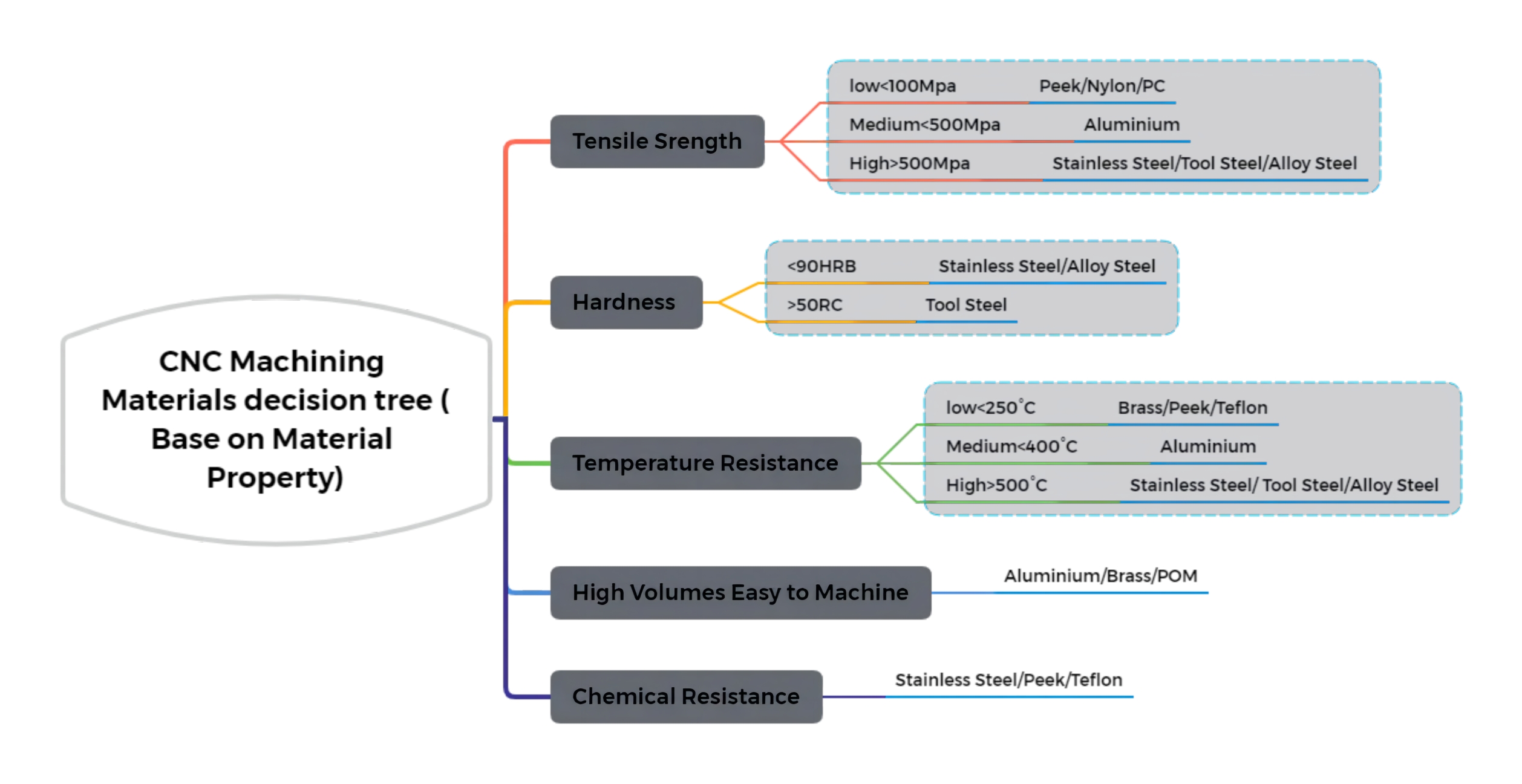

CNC Machining Material Guide

Type |

Tolerance |

No Drawing |

| Linear dimension |

+/- 0.025 mm +/- 0.001 inch |

ISO 2768 Medium |

| Hole diameters (not reamed) |

+/- 0.025 mm +/- 0.001 inch |

ISO 2768 Medium |

| Shaft diameters |

+/- 0.025 mm +/- 0.001 inch |

ISO 2768 Medium |

| Part size limit |

950 * 550 * 480 mm 37.0 * 21.5 * 18.5 inch |

ISO 2768 Medium |