OEM Aluminum Heatsink Die cast & CNC Part Heatsink ADC12 / A380 ,OEM Part Manufacturer Aluminum/Zinc/Brass/Alloy Metal/Steel/Iron Gravity/Sand/Die Casting & CNC Machining

Aluminum die-cast heatsink is widely used in many fields such as Automobile, Electronics, Electrical appliances, Medical treatment and so on.

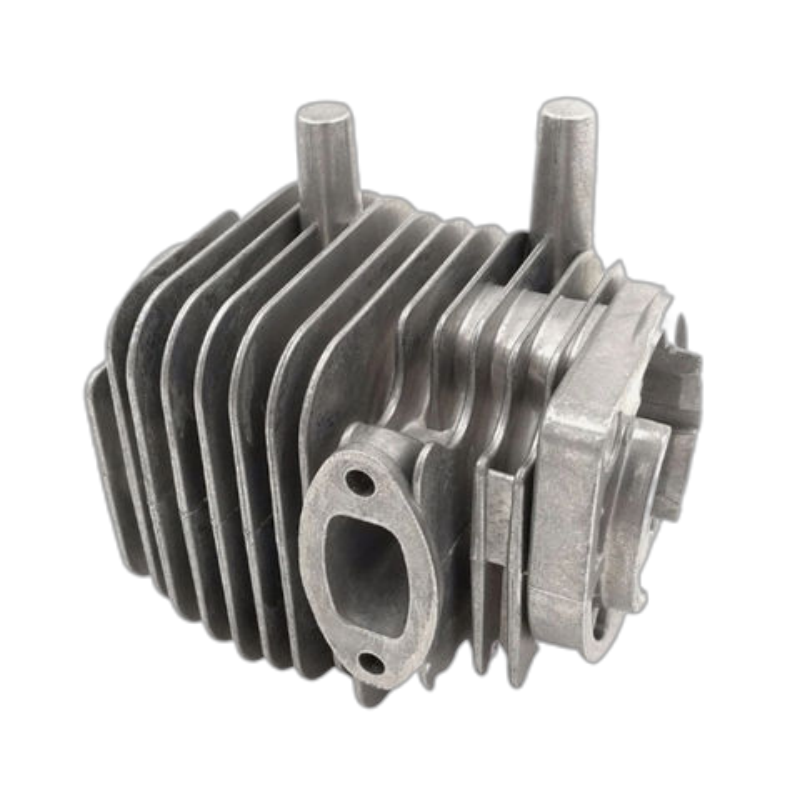

Products

Products DETAILS

OEM Aluminum Heatsink Die cast & CNC Part Heatsink ADC12 / A380 ,OEM Part Manufacturer Aluminum/Zinc/Brass/Alloy Metal/Steel/Iron Gravity/Sand/Die Casting & CNC Machining

Aluminum metal has excellent characteristics and is widely used to make heat dissipation parts of various specifications:

1. Metal aluminum has excellent thermal conductivity and heat dissipation characteristics.

2. Metal aluminum is non-magnetic and has strong oxidation and corrosion resistance.

3. Metal aluminum has strong plasticity and can be made into parts with various complex shapes and sizes through hot die casting to meet the needs of heat dissipation.

4. Metal aluminum has low density and light weight, which greatly reduces the weight of the product.

5. Metal aluminum has abundant sources on the earth and is easy to obtain, so the price is low.

6. Metal aluminum parts can be subject to various surface treatments, such as wire drawing, sand blasting, electroplating, laser engraving silk screen printing, anodizing, etc. under the surface treatment process, the radiator shell with exquisite surface, superior and stable performance can be cast.

--------------------------------------------------------------------------------------------------

Application of aluminum heatsink:

1. Computers and other electronic products, such as CPUs and graphics cards, have a closer look. Their radiators are mainly made of aluminum.

2. Audio, LED lighting, home appliances and many other fields.

3. The greater use of aluminum profile radiator is reflected in large functional devices, such as energy vapor vehicle, power supply industry, energy storage industry, photovoltaic wind power industry, return welding machine industry, SVG, IGBT, frequency converter, inverter, etc,

4. Mechanical motor, automobile and power battery pack, engineering operation machinery, IGBT, air compressor, railway locomotive, thermal components of household appliances and other industries.

The material used for aluminum die casting

ADC12, ADC10, A380, A383, B390, 413, AllSi9Cu3, AlSi10Mg, LM6, LM9, LM25, YL102, etc.

Dimensions,surface finish and tolerance of diecasting parts we make

Surface Finish of: Plating, Painting, Powder Coating, Polishing, Stoving Varnish, Anodizing

Heat treatment: Annealing treatment, Solution treatment. T1, T2, T3, T4, T5, T6.

Unit weight: 5g-45kg

Dimensions: <=1500mm, Min Wall Thickness 0.6mm

Machining tolerance: +/- 0.005mm

Certificate: ISO9001,ISO14000, RoHS, SGS

| Product name | Aluminum heatsink, Aluminum radiator: |

| Product material | ADC12, ADC10, A380, A383, B390, 413, AllSi9Cu3, AlSi10Mg, LM6, LM9, LM25, YL102, etc. |

| Dimension accurcy | IT4 – IT8 (as required) |

| Equipment & machine for production | Die asting machines:180T, 280T, 400T, 600T, 800T, 900T, 1200T, 1650T, 2000T |

| Material of die casting mold |

H13,SKD61,8407,8417 |

| Life of die casting mold | 50,000~300,000 cycles |

| Post process | CNC machining, polishing, powder coating |

| Packaging | polybag, foam cushion,carton box, wooden cabinet |

| Lead time | 15~25 days |

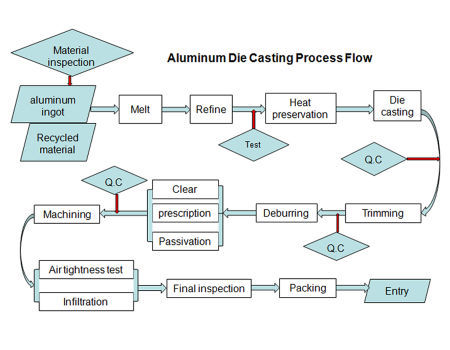

Aluminun die casting process

Tools and equipment we use in producing aluminum die casting

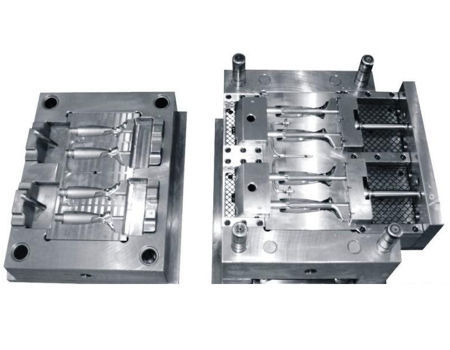

(1).Die casting mould:Mould material: H13 hot die steel

(2).Die casting machines: 120T-3500T

Die casting machines of 180T, 280T, 400T, 600T, 800T, 900T, 1200T, 1650T, 2000T and 2500T

(3).CNC lathes, CNC machining centers (4 and 5 axis), and a variety of auxiliary equipment, a total of more than 30 sets, can be for turning, milling, grinding, drilling, tapping and other processing.

(4).Our testing equipment includes: coordinate detector (3 sets), spectrum detector (2 sets), X-ray defectoscope (3 sets), secondary projector, tension tester, salt spray tester, etc.

(5).A mold workshop, wire-cutting, EDM, CNC machining center, mold testing platform and other equipment, can develop and produce die casting molds below 2500T equipment.

Die casting workshop Die casting mould

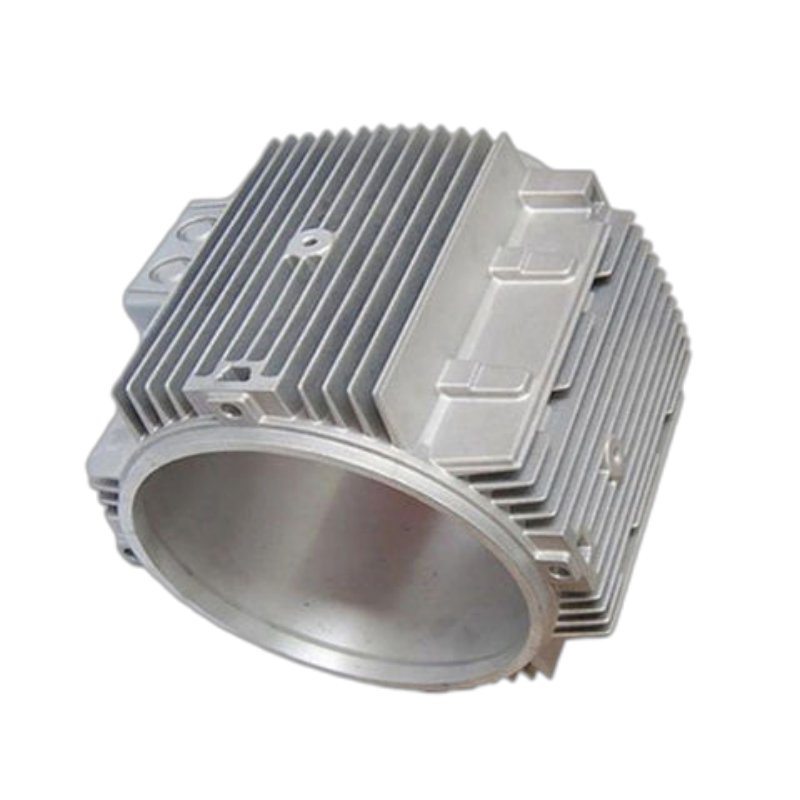

Aluminum heatsink box

Aluminum heatsink box

Aluminum heatsink with powder coating

Necessary information for a quotation:

1. Product parts list: Includes the part name, dosage, materials and surface treatment contained in the product.

2. Product design drawings: 3D drawings, STP and IGS format documents.

3.2d drawing, specifying product dimensional accuracy requirements and local processing requirements.

4. Forcast.order

5. Package