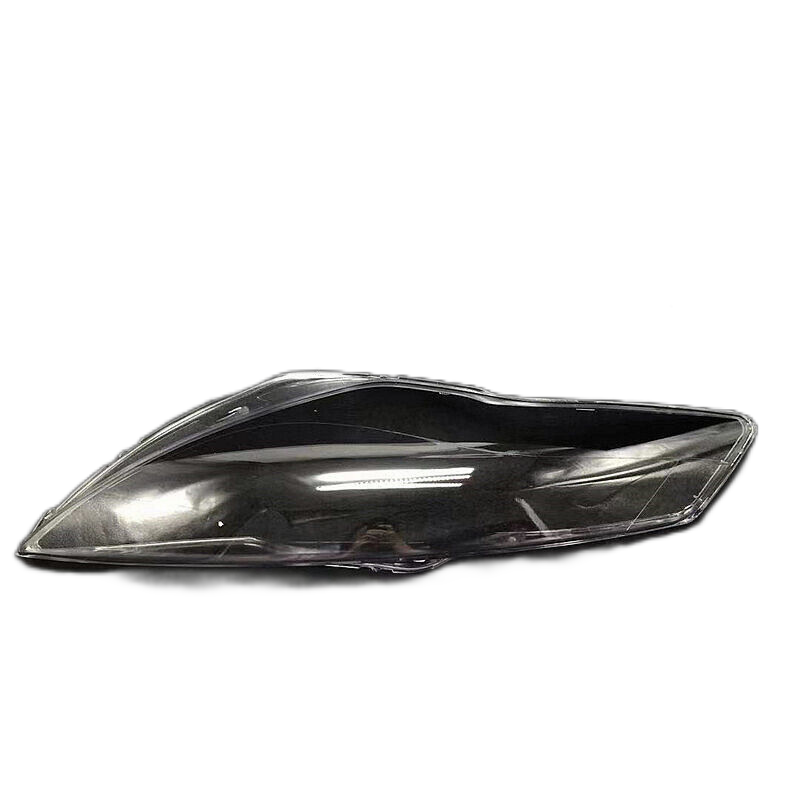

Lens / Lamp OEM Automotive injection molding part , Automotive tail light cover and its injection mold , Headlight Headlamp Clear Lens Cover

Dedasun's Service Always Go Extra Mile ! We offer one-stop services: Design Feedback Modification Suggestion, Rapid Prototype Design And Making Services, DFM Report, Mold Flow And Mold Design, Injection Mold Tool Making Services, Plastic Injection Molding Services, Post Processing And Assembly Services.Professional mold manufacturer Mainly engaged in the development and production of plastic molds for automobiles and Medical Devices, and the mold products cover various large and medium-sized injection molds.

Products

Products DETAILS

Lens / Lamp OEM Automotive injection molding part , Automotive tail light cover and its injection mold , Headlight Headlamp Clear Lens Cover

1.Product

Material: PC , Dimension: 210mm*148mm*56mm , Color: Clean

Surface: Smooth hardening , Post processing: surface

Packing: Outer surface protected with film, eachpart in a polybag

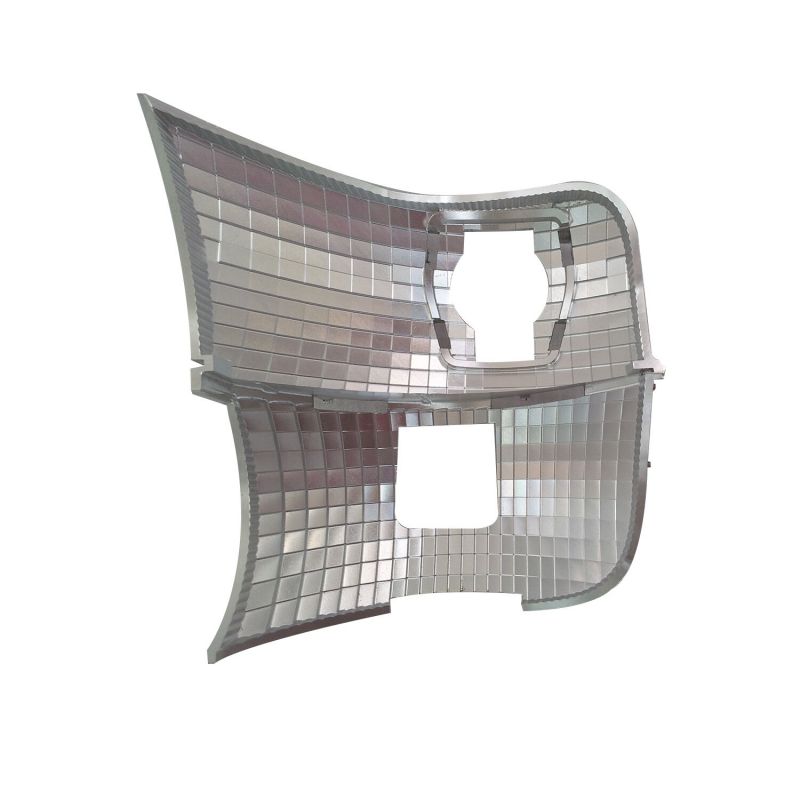

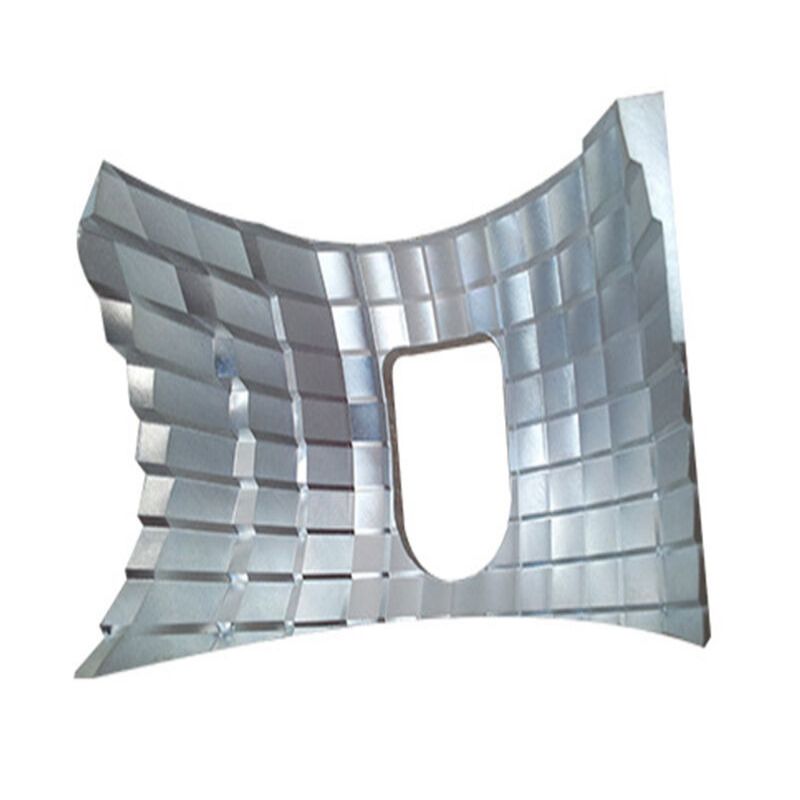

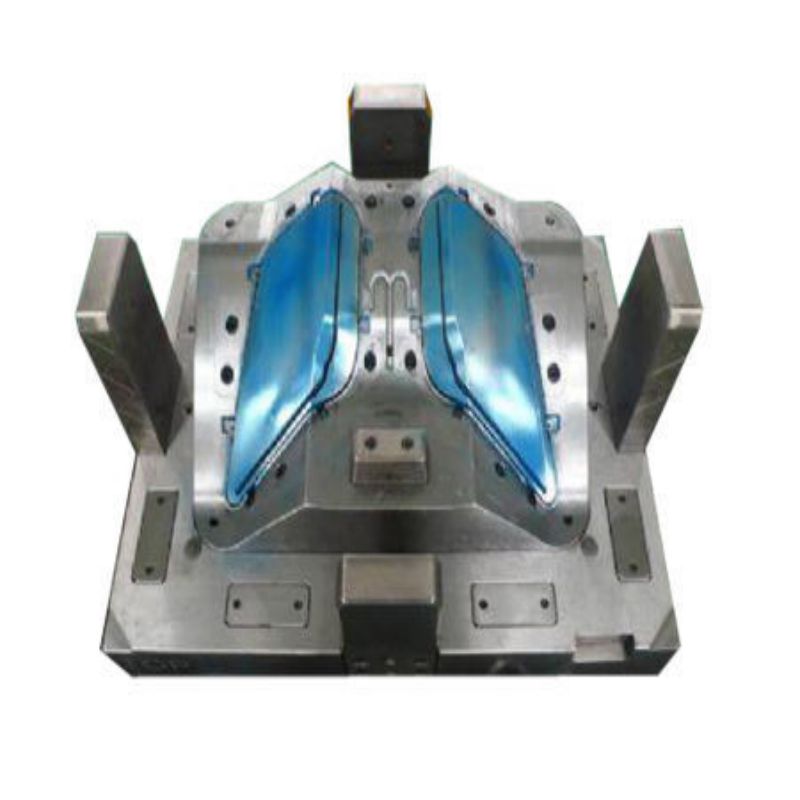

2.Mold

Mold style (Customized): LKM or customer specify

Mold types 2 Plate , Lead Time: 35days

Mold life: 500,000 shots or customized , Mold base:LKM , Mold cores' Material:S136H ,

Cavity: 1*1 , Hardness: HRC48-52 , Runner system:Cold runner

Gate type: Open system , Sample submission time: Within 2days after testshot

Injection machine: 200tons , Surface treatment: Polished , Design Software: UG,Proeng

R&D Engineer Team

We have our R&D engineer team with engineers of 6~10 years' professionalexperiences in products design and mold design.We use CAD, UG and and Flow-3D, as well as mold flow simulation analysis software.the company ensures high efficiency and effectiveness, and risk reduction in the process of design.

The Mold Workshop

We have our mold workshop, with full range of machines for mould making: 30 CNC ,15EDM, 8 wire-cut, and 15 other machines and equipments , with 25 technical workers.

The Injection Molding Workshop

Dedasun is capable of producing precise, highly repeatable components, making it an ideal manufacturing method for lighting lenses, covers, and housings on an automobile. Both interior and exterior lighting uses this manufacturing method to create high-quality, high-finish lighting that is complementary to the designer’s vision and the finish of the vehicle.

Newer vehicles have distinctive designs for lighting like light pipes, light bars, and thicker multi-layer lenses which require a unique mold to make the product. Dedasun works well with these innovative designs and can quickly be set up to manufacture high or low quantities as desired.

With the development of plastic material science, transparent plastic has replaced glass to make lampshade. The production of lampshade by injection molding has become the main way of mass production of automobile lampshade.

Features of automotive plastic lampshade:

1.The plastic lampshade is light in weight.

2.Polycarbonate PC can withstand high temperature, high hardness, scratch resistance, 80-90% light transmittance.

The modified polycarbonate has the advantages of high hardness, high strength, high toughness, good UV resistance and light transmittance, and stable chemical properties of acid and alkali corrosion resistance.

3.Compared with glass, plastic has strong elasticity, and the downstream buffer will not be easily broken without severe impact.

4.In order to meet the optical and aesthetic requirements of lamps, the surface of lampshade is often made into multi curved surface, and the internal structure also fully considers the perspective and reflection requirements of light.