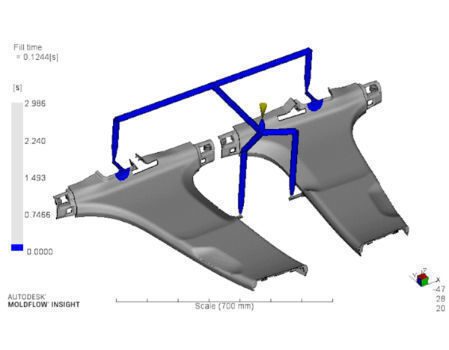

CustomIzed Automotive Headlight Bottom Base Case Housing , Injection Molding , Auto Plastic Housing

Custom Injection Mold & Injection Molding Factory .Dedasun Is A Top-End Turnkey Manufacturing Company. We Provide Plastic Injection Mold Making, Custom Injection Moulding Products And Help Wholesalers And Brand Owners Fulfill Their Products.

Products

Products DETAILS

CustomIzed Automotive Headlight Bottom Base Case Housing , Injection Molding , Auto Plastic Housing

Basic Specifications:

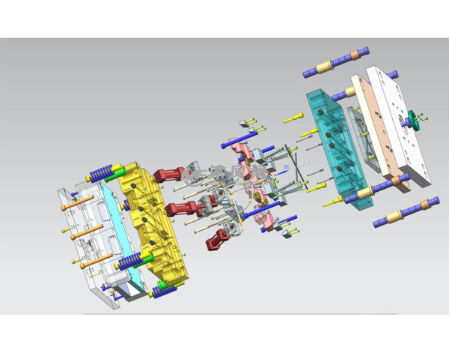

| Place of Origin: | Shenzhen, China (Mainland) | Product Material: | PP/PC/PE/ABS/PVC/PS/Nylon | Mould materail: | P20,718,738, NAK80 , S136 , SKD61 etc |

| Shaping Mode: | Plastic Injection Mould | Mould cavity: | single/multi | Surface treatment: | Mirror Polish |

| Mould base: | LKM | Design software: | UG PROE CATIA SOLIDWORK… | Mould delivery: | by sea |

| Type: | CNC Process | Mould life: | 250000-300000shots | Supply Ability: | 2400 Sets/Year |

| Packaging Details: | Plastic film sealed and PLY wooden case or as your requested. |

| Port: | Shen Zhen / Guangzhou |

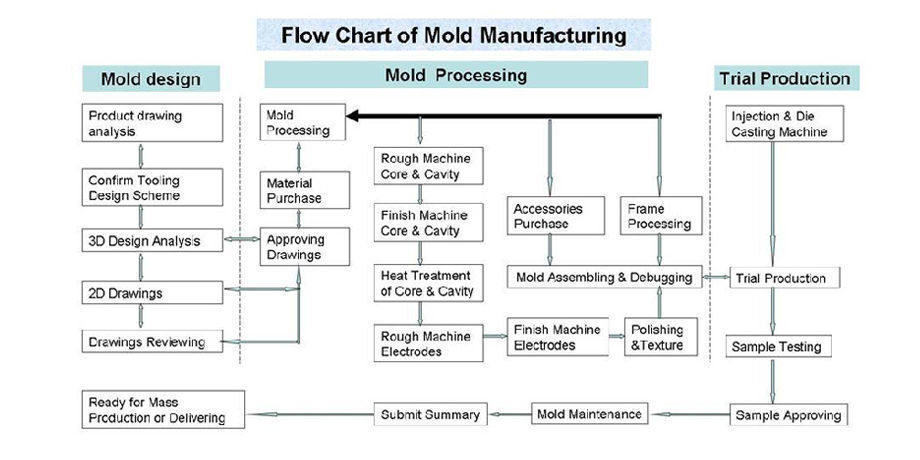

| Lead Time: | 60days after received the deposit and design drawings. |

Our advantages:

①Technical team

Our company has a strong technical team which has long time working and production experience, design molds with 3D nano tiny texture in nano embossing technology.

②Custom moulds

According to clients' demand, we customize texture mold , merge texture, window, logo, button into one, and complete all work flows with high efficiency in a short time.

③Technological innovation

In PET,PC,PMMA,glass and other non-metallic materials surface to make metal color and texture.

Injection Molding Custom Cheap Black Auto Plastic Bracket Automotive Plastic Reflector

- Our equipment

Equipment for mold tooling:

- CNC machines: 30 sets

- Electric discharge machine : 15 sets

- Wire cutting machines/ slow-feeding NC wire-cut machine: 8sets

- Milling machines, plain grinding machines. drilling machines : 15 sets

- Equipment for injection molding:

- Injection machines : 15sets (100Tons~1500Tons)

- Double injection machines: 3Sets

- Measurement equipment : 100 sets

- 3D coordinate measuring machine 2 sets

- 2D projector 1set

- Our capacity:

- Over 20 sets molds per month. Standard: HASCO. DME, LKM, Non-standard

- Monthly production of plastic products 400,000~600,000 pieces. Including post processing: painting spray, printing, e-plating.

- Monthly production of machined metal part 100,000~200,000Pieces.Including aluminum & zinc die cast, steel machining , stamping.

Payment terms:

Molend charge: 50%~70% deposit on start mold tooling,the balance is paid off when mold is accepted for production .paymt for goods: 50%~70% deposit on order,the balance is paid off when the goods is ready for delivery.

Shipping and Business Terms:

Time for mold tooling:25~40 workdays (depends on the product design)Lead time for product delivery:7-15 workdays (depends on the volume of order and post processing)Sample is possible.The sample price and freight is determinded by the actual cost.FOB Shenzhen, China.