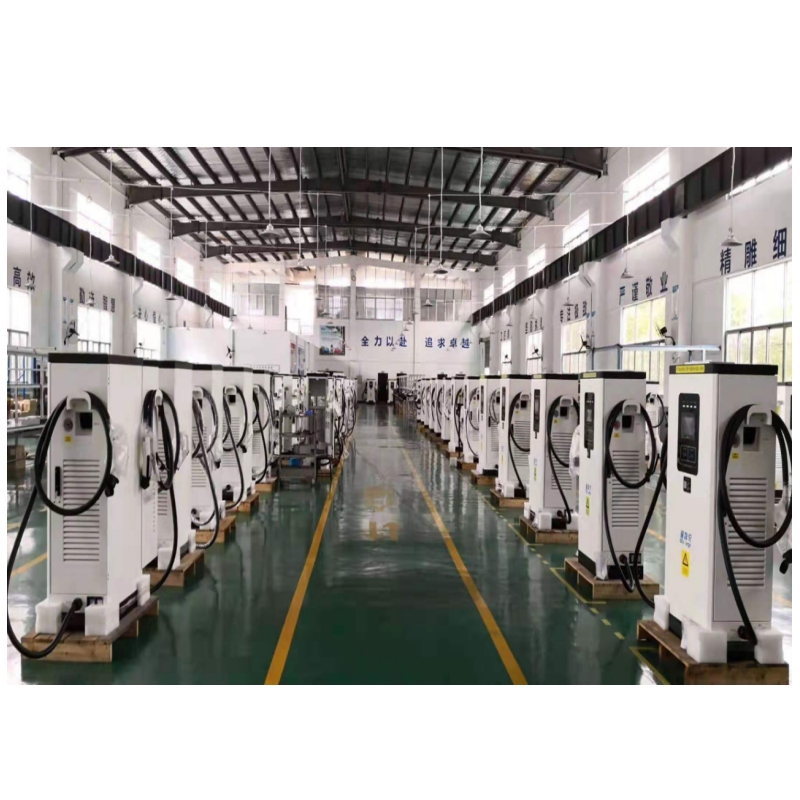

Custom Sheet Metal Fabrication for New Energy Automobile Charging Stations

Products

Products DETAILS

Custom Sheet Metal Fabrication for New Energy Automobile Charging Stations

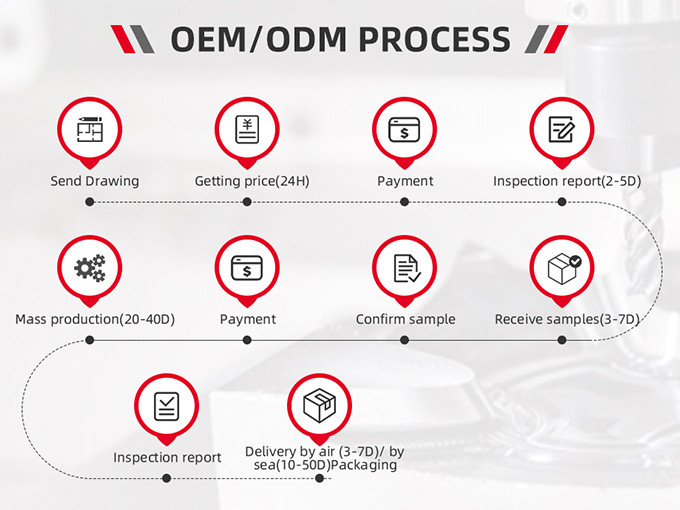

The customized processing flow for sheet metal components of new energy vehicle charging stations involves a meticulous sequence of steps to ensure precision and quality. Key processes:

-

Material Selection: The initial step involves carefully selecting sheet metal materials based on the charging station's design specifications, performance requirements, and durability considerations.

-

Design and Engineering: Detailed design drawings are created, incorporating the specific dimensions, shapes, and features required for the sheet metal components. Engineering expertise ensures the designs are structurally sound and suitable for the intended application.

-

Cutting and Preparation: The selected sheet metal is precisely cut to size using advanced cutting techniques like laser or waterjet cutting. This ensures accurate and smooth edges, ready for further processing.

-

Forming and Stamping: The cut sheet metal undergoes forming and stamping operations to achieve the desired shapes and contours. This involves the use of precision tooling and stamping machines to create intricate features and structures.

-

Bending and Folding: The formed sheet metal is then bent and folded according to the design requirements, creating the necessary angles and curves for assembly.

-

Welding and Assembly: The individual sheet metal parts are welded together using robust welding techniques to form a sturdy and secure structure. This ensures the integrity and strength of the charging station's enclosure.

-

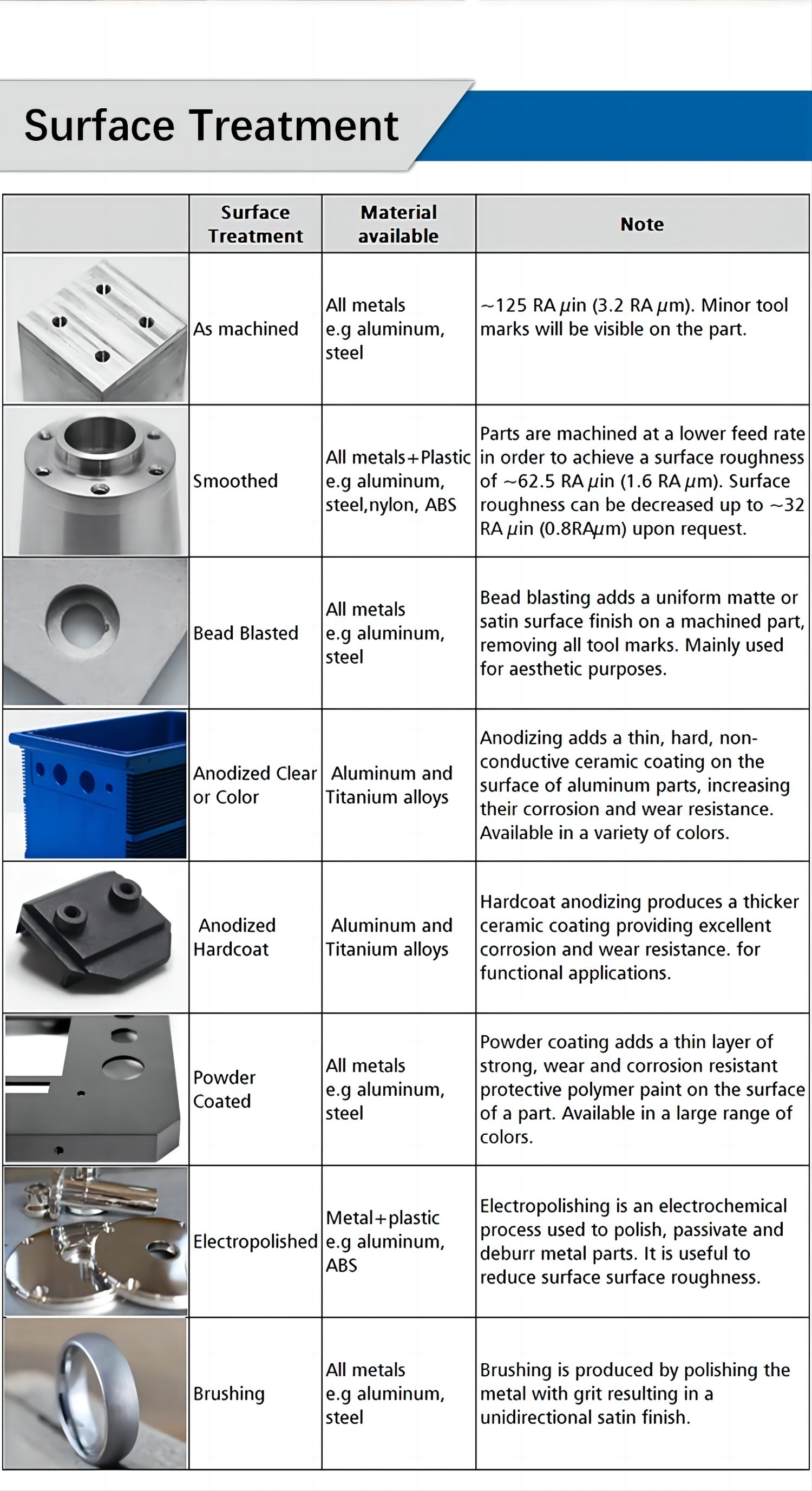

Surface Finishing: The welded assembly undergoes surface finishing processes such as painting, powder coating, or electroplating. This not only enhances the aesthetics of the charging station but also provides corrosion resistance and durability.

-

Quality Control and Inspection: A rigorous quality control program is implemented throughout the entire process. Each stage of production is carefully inspected to ensure compliance with design specifications and quality standards. This includes checks on dimensions, weld quality, surface finish, and overall structural integrity.

-

Packaging and Delivery: Once the sheet metal components have passed all quality inspections, they are carefully packaged to protect them during transportation. The final products are then delivered to the customer, ready for installation and use in new energy vehicle charging stations.

By following this comprehensive processing flow, we ensure that the sheet metal components for new energy vehicle charging stations are manufactured with precision, reliability, and durability, meeting the high standards expected in this industry.