Medical Devices Customized sheet metal fabrication

Low-volume and precise production parts in as fast as one day

Quality certifications: ISO 9001:2015 / ISO13485

Heathcare metal enclosure suppliers, manufacturers, factory, customized

Progressive die, Bending,Welding ,Brushed Anodized

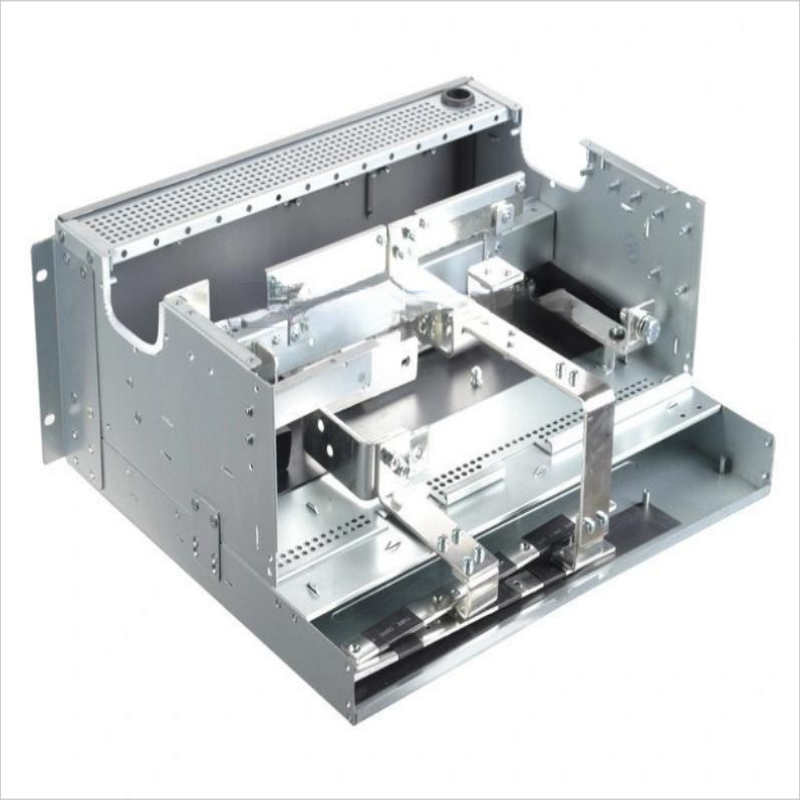

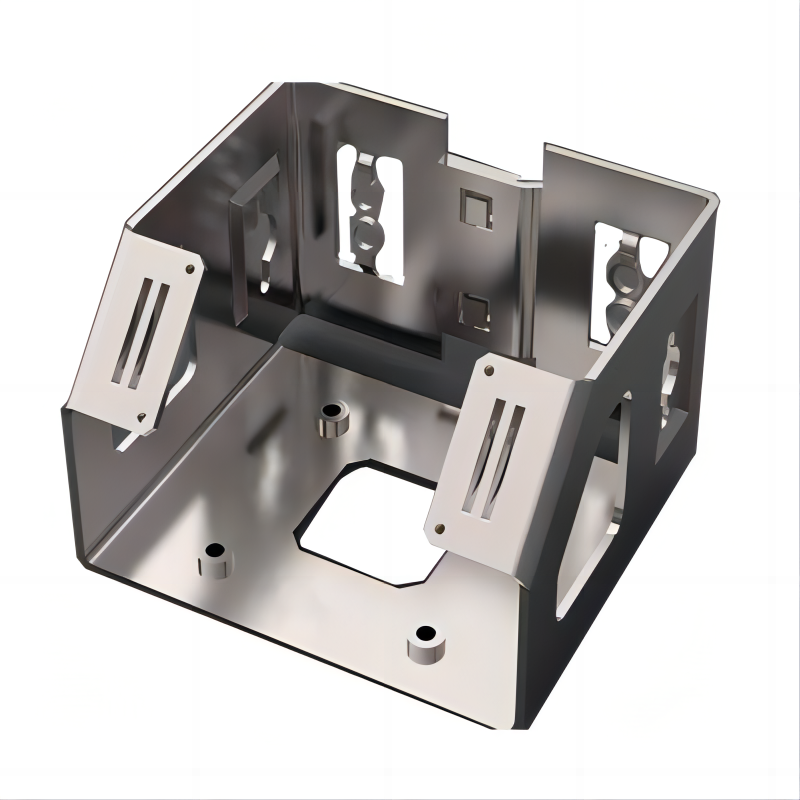

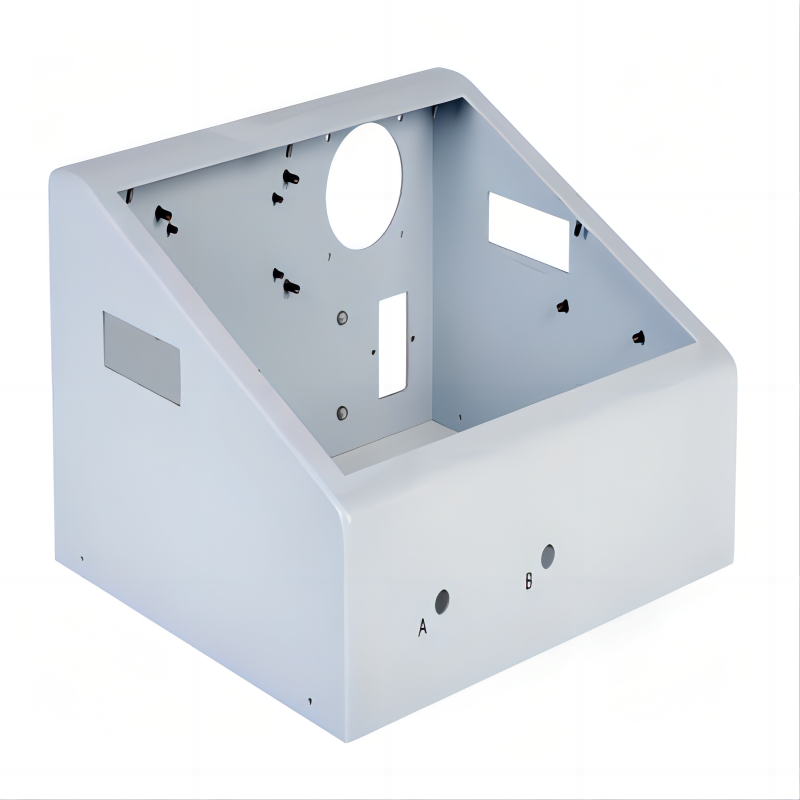

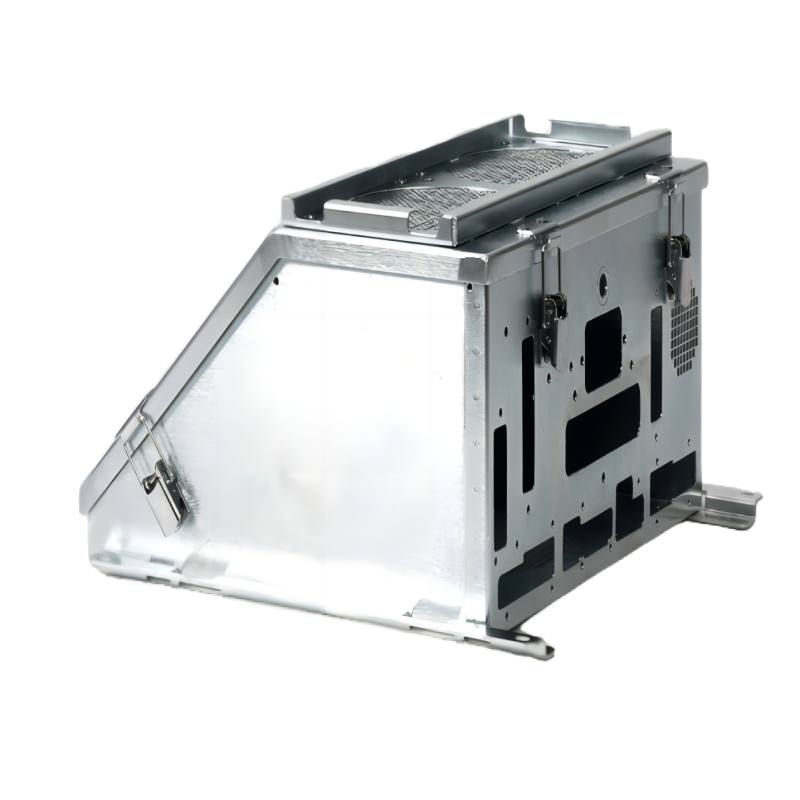

Aluminum Chassis Box, OEM metal boxes, enclosures,Chassis

Products

Products DETAILS

Medical Devices Customized sheet metal fabrication

We Are Top Medical Sheet Metal Parts Fabricators

Item Name

OEM customized;Aluminum manufacturing;Pressing Components;Metal fabrication with iridite finish

Quality Assurance

ISO9001 Certified , ISO13485 Certified

Machining Equipment

Laser Cutting Machine/CNC Shearing Machine/Flat Bed Spot-welder

Die Grinder/Double Servo Turret-type Punch Press/Bending Machine etc.

Materials

Carbon steel /Mild steel/ Cold roll steel/ Hot Roll Steel/ Zinc Plate/ Stainless Steel/ Aluminum/ SECC/SGCC/SPCC/SPHC/ Other metal

Thinckness:0.1/ 0.2/ 0.3/ 0.4/ 0.5/ 0.6/ 0.8/ 1.0/ 1.2 / 1.5/ 1.2/ 1.3/ 1.5/ 3.0/ 3.5/ 4.0/ 4.5 / 5.0/ 6.0

We handle many other type of materials. Please contact us if your required material is not listed above

Surface Treatment

Blacking,Polishing,Anodize,Chrome Plating,Zinc Plating,Nickel plating,Color Zinc-Plated,Iridite Per ASTM B921 Class1A|TypeII |Colorless

Service

OEM / ODM / Customized / Design

Application

Medical Devices Industry

File Formats

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc.

Sheet metal Medical Parts Prototyping and Manufacturing

- design for manufacturability (DFM) feedback on every quote

- ability to prototype in production-grade materials

- low-volume and precise production parts in as fast as one day

- diverse materials (high-temperature plastics, medical-grade silicone rubber, and hundreds of plastic, metal, and elastomeric materials)

- quality certifications: ISO 9001:2015 / ISO13485

- post processing such as anodizing and plating

Sheet metal Manufacturing for Medical Device Applications

- Handheld devices

- Surgical instruments

- Enclosures and housings

- Ventilators

- Implantable prototypes

- Prosthetic components

- Wearables

- Cartridges