Plastic Injection & Molding for Cosmetic Medical Machine Chassis ,OEM Mold Injection Cosmetic Medical Machine Plastic Enclosure, Aesthetic Medical Frame Plastic Injection Mold Making

The plastic injection molding services provided by Dedasun are determined as the most widely utilized service for plastic tools.We use very highly maintained procedures that convert the Thermoplastics by utilizing Thermosetting polymer production.We offer custom-made services to the cosmetic medical industry to produce plastic injections.

To ensure quality, we use molded plastic parts that go through a process that makes them extremely strong and easy to use. This process is known as the fabrication of plastic parts in the medical industry.

Customer choose Dedasun because we vigilantly care for all their needs.

We also use the processes of sheet metal fabrication, casting and CNC machining for the manufacturing of cosmetic medical products.

Products

Products DETAILS

Plastic Injection & Molding for Cosmetic Medical Machine Chassis ,OEM Mold Injection Cosmetic Medical Machine Plastic Enclosure, Aesthetic Medical Frame Plastic Injection Mold Making

What We Made For Medical Industry

We offer high end services to the medical industry and have been doing it for a very long time. The use of these medical products is extremely necessary for the medical field. We provide high quality materials, typical accuracy and the best application of these medical products. Our several different manufacturing processes include plastic injection molding, CNC machining process and sheet metal fabrication. All these serve as the greatest forms of manufacturing processes used by our expert engineers at Dedasun.

| Product Name: | Aesthetic Medical Frame Plastic Injection Part | Mould making service: | OEM/ODM | Design software: | Pro/E, UG, Solidwork, Moldflow, AutoCad, etc. |

| Parts material | ABS, PC, PP, PBT, BMC, PMMA, PC+ABS, PP+TD20%, PU, PE, PVC..Etc | Cavity number | Single or Multi | Mould Life | 300,000 - 1,000,000 shots |

| Core & Cavity steel | NAK80, S136, SKD61, P20,1730hh, 2738hh, 718h, H13, BPMHH, 2343hh, etc. | Runner | Hot or Cold | Mould Base | LKM, DME, HASCO, ETC. |

| Gate point | Edge gate, Slid gate,Sub gate,Direct gate, Pin point gate, Valve gate, etc. | Injection machine | 90T-1500T | Surface Treatment: | Painting , Printing ,Gold stamping,In-Mold Decoration (IMD) , Electroplating , Vacuum Metallizing |

| Mold base steel | 45 Steel, S55C, P20, 1730, 2738, 718h, H13, BPMHH, 2343ESR | Cycle time | 10-120 seconds | Tolerance | +/-0.05~+/-0.01mm |

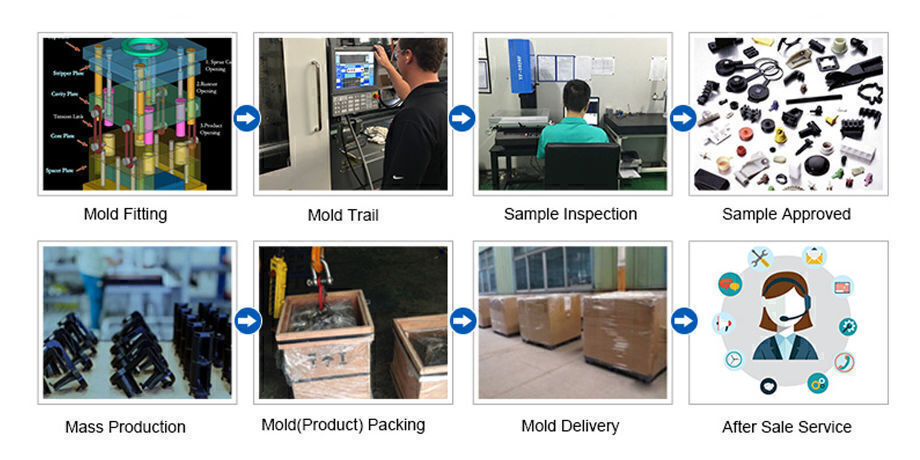

Producing Process:

Audit drawings - Mold flow analysis - Design validation - Custom Materials - Mold processing - Core processing - Electrode machining - Runner system processing - Parts Processing and Procurement - Machining Acceptance - Cavity Surface Treatment Process - Complex Mode Die - The entire mold surface coating - Mounting Plate - Mold Sample - Sample Test - Sending Samples

Dedasun has years of experience making parts for customers in the medical and healthcare field, producing medical devices, medical equipment components, anatomical models, and more. From early-stage prototypes to final parts, we have the facilities and expertise to realize even the most complex designs.