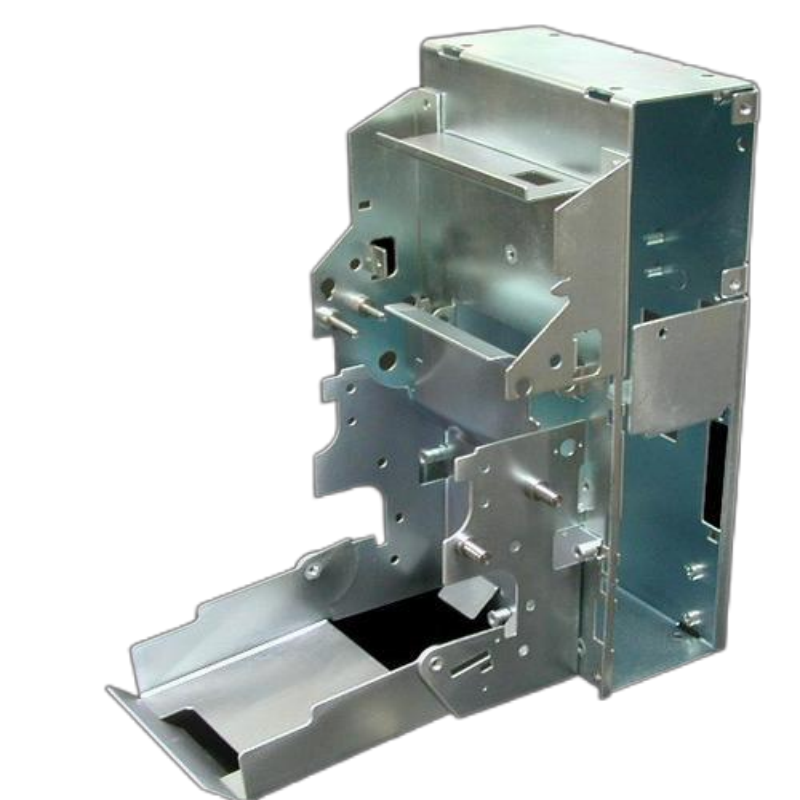

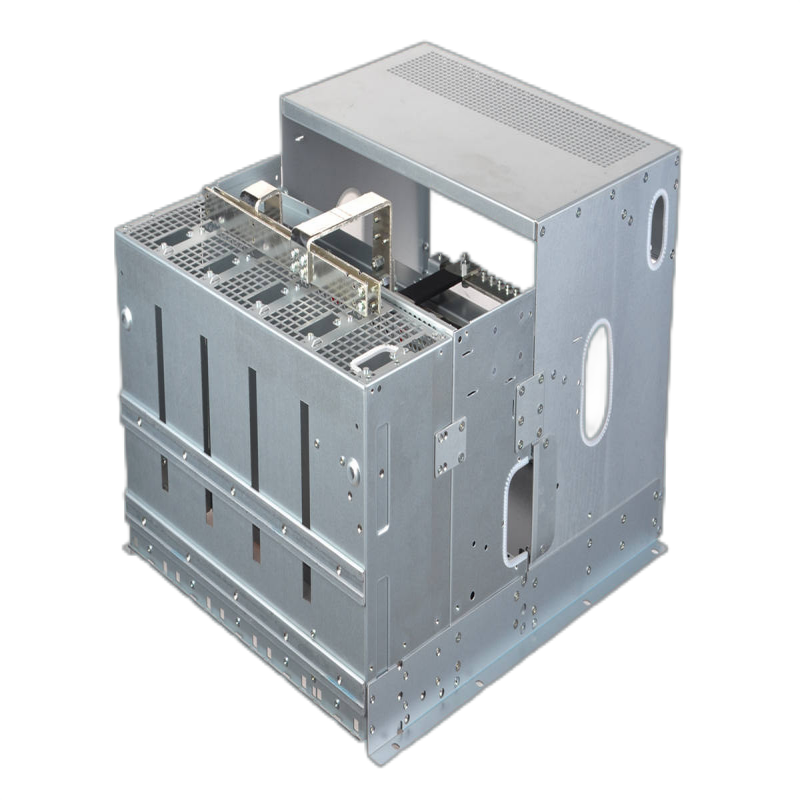

Medical Devices Chassis Riveting& Welding & Assembly

Medical Devices Metal Housing

Medical Devices Kiosk Enclosure

Riveting & Welding & Assembly Chassis

Zinc Coating /PVD /Tin Plating /Gold Plating /Iridited /Alodine /Anodizing/Silk Screen /Laser Marking /Powder Coating

Products

Products DETAILS

Medical Devices Chassis Riveting& Welding & Assembly

Dedasun produces custom complex Chassis / enclosures for the Medical Devices industry.Using a full range of metals and finishes to suit individual customer needs, Dedasun profides engineering, finishing, and final assembly of custom sized Chassis / enclosures.

| All Outputs Certified | ISO 9001:2015, ISO13485, ROHS and UL |

| Color | Silver.. Blue, Yellow, Green, etc. as options |

| Finish | Powder Coat / Zinc Coating / PVD / Tin Plating / Gold Plating / Iridited / Alodine / Anodizing / Nickel plating / Passivation /Brushing / Electropolishing |

| Design / Cooperation model | OEM or ODM ; As per customer specific requirements or customer give us the specified sample; or the customer conceptual or preliminary design; or the customer sketched idea. |

| Accept drawing format | jpg / .dwg / .igs / .stp etc. |

| Material | Normal Metal, and includes Stainless steel, Alumium,CRS , carbon steel, Brass,Copper, Nickel,Plastic and others. |

| Material condition | On flat sheet, plate coil supplying condition ;Hot rolled or cold rolled or cold drawn for options. |

| Material thickness | From 0.1mm~10.0 mm |

| Application material standard |

If there is no any specially requirement, we often sugguest our customer to try the equivalent China National (GB) standard material that our engineering team proposes which to be properly converted from ANSI, ASTM, SAE, EN, DIN, BS, JIS, and etc., to contribute the material cost control. If it is necessary to use exact designated material no., it is also possible choice. |

| Available processing (Technique) | - Shearing - Crimping - Laser cutting- Bending- Stamping - Pressing - Deep drawing - Rolling - Forming - Fabricating - Drilling - Tapping - Riveting - Spot welding - TIG - Assembling |

| Precision | Average level: ±0.05mm, depending the part size and thickness and material |

| Tooling in house | To design and build the necessary tooling in own house, for the tooling we never add any margins, it just cost. |

| Hardware | Screws, PEM NUTS, CAM Locker, Fans, Bussbar, Copper Cable |

| Lead Time | 2~3 weeks for prototyping. 4 weeks for production |

Key Features:

1) In house Molding / Tooling Designing and Manufacturing

2) Pre-assembled to simplify installation of entire solution

3) Supports a wide range of aesthetic options including glass/acrylic, multiple colors, vinyl wraps, etc..

4) With 6800 Sq-meter facility equiped with high-level machines, we provide One-stop solutions to customers in the world.

Packing Details :

1) Strictly in accordance with the customer specific instruction on the packing;

2) We can package for retail if needed;

3) If no any specified, generally we would recommend that the parts to be packaged by a poly bags, then put them in cartons, and finally to be on the pallets. The gross weight of one carton is not more than 22kg and pallet size try to approaching 120cm×80cm (Europe size) and 42"×42" (US size);

4) The package is seaworthy and suitable for export. The woodern package material shall be steamed with the certificated and stamped by CCIB;

5) We will carefully give our packaging suggestion or packing according to your requirement;

6) We can arrange the air freight and sea freight for customers to all over the world;