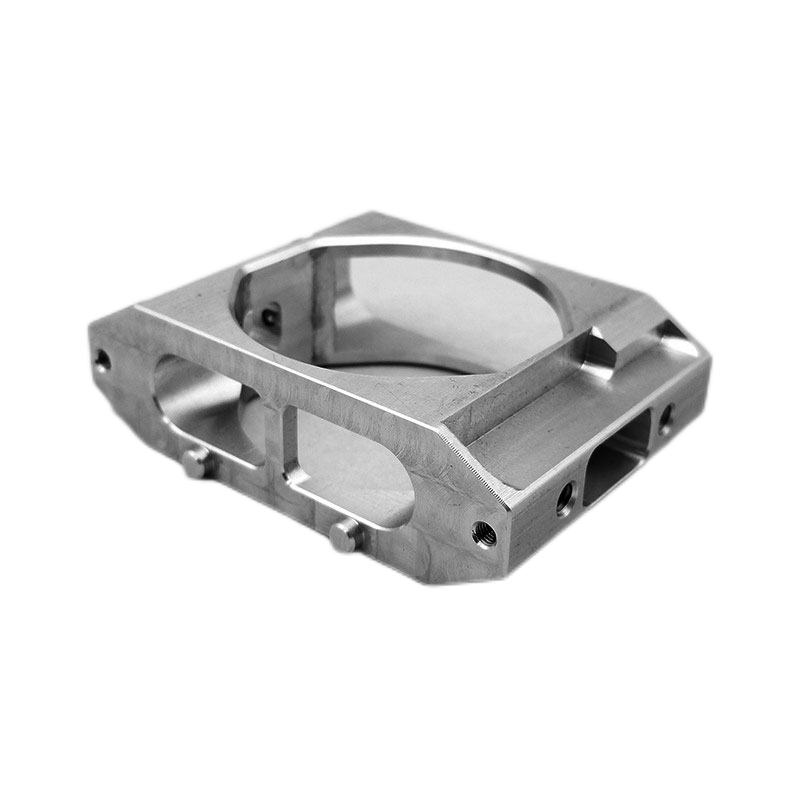

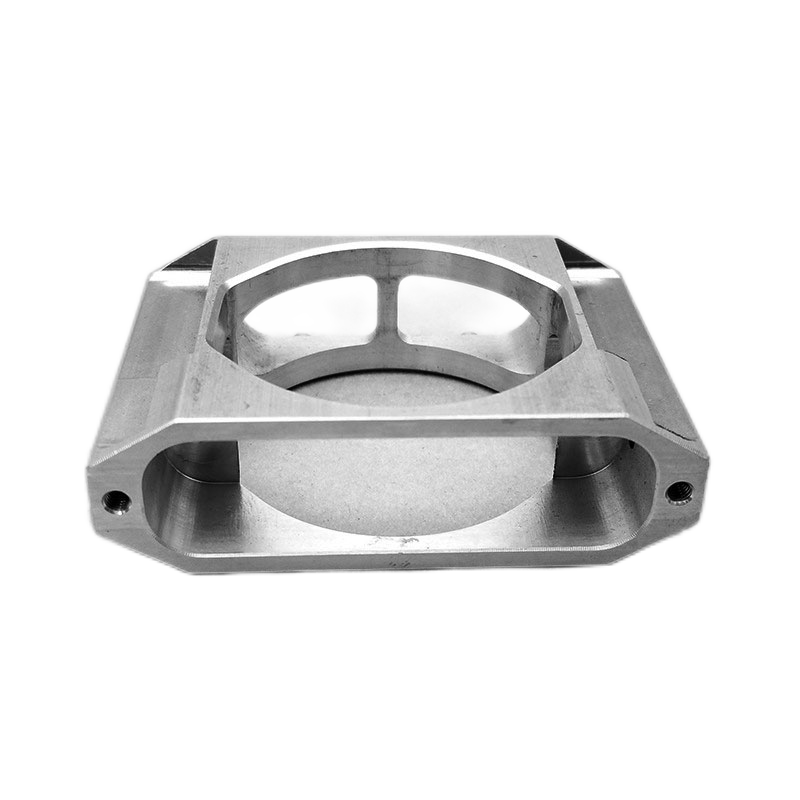

CNC Customized Underwater Digital Camera Metal Enclusure

Optical product manufacturers in the optics industry often face significant challenges due to the extremely tight tolerances, demanding quality control standards, and the need for visually appealing aesthetics. However, our expertise and cutting-edge machinery position us well to tackle these challenges. We are well-versed in the challenging manufacturing requirements involved in the optical industry, including fine threading, precise positioning, and superior surface finishes.

At Dedasun, we consistently assist our customers in designing custom optical components in compliance with specific requirements and specifications. Our skilled machinists well comprehend how each component fits within the overall project and its intended application, enabling them to effectively machine parts that perfectly fit into the assembly.

Products

Products DETAILS

CNC Customized Underwater Digital Camera Metal Enclusure

CNC Machining of Optical Parts from Prototype to Production

Given the nature of the optical industry, it usually requires multiple trials before commencing mass production, making it crucial to work with a manufacturing partner with extensive flexibility in their production capabilities. Our customers frequently demand a swift transition from optical part prototypes to mass production, and at Dedasun, we are fully equipped to fulfill these requirements.

As an advanced CNC machine shop in China, we have the capacity to handle production volumes that span from rapid prototyping of a single part to mass production runs of up to 50,000 parts. Furthermore, our top-notch CNC lathe equipment allows us to provide customers with shorter lead times for part delivery.

CNC lathes and 5-axis CNC machines equipped in our machine shop have incredible flexibility to make custom optical parts and components with high precision and quality. As a result, our precision CNC machining services for optical components are highly sought after throughout the industry.

No+Color: Custom

Surface treatment: Anodize

Product material: Aluminium

Proofing cycle:7 days(100000 pcs/M)

Application:Precision Cnc Machining

Machining factory:Dedasun

Product Category: Optical Parts

Production Process:Cnc Machining

Size: According to customer's drawings

Services Range

-

ODM&OEM service are all welcomed

-

Practicable Software: Solidworks,Pro/Engineer,Auto CAD,PDF,JPG

-

Small orders accept

-

Reasonable and competitive price according to your drawings

Quality Control

-

Technicians self-check in production

-

Engineer spot check in production

-

QC inspects after mass production finished

-

International sales who were trained the technical know-how spot check before shipping

- ODM&OEM service are all welcomed

- Practicable Software: Solidworks,Pro/Engineer,Auto CAD,PDF,JPG

- Small orders accept

- Reasonable and competitive price according to your drawings

- Technicians self-check in production

- Engineer spot check in production

- QC inspects after mass production finished

- International sales who were trained the technical know-how spot check before shipping

Materials Available for Optical CNC Machining

In the field of optical measuring and metrology, even the slightest manufacturing flaws in machined parts can have a severe impact on the performance of measuring devices. It is crucial that all components, ranging from the device housing to the base plate, are constructed using materials that offer the necessary stability to ensure precise and consistent results.

As an example, the frames of the coordinate measuring machine (CMM) are often constructed using a combination of aluminum alloys and ceramics, aiming to enhance the rigidity of the apparatus, particularly for the Z-axis direction, which is crucial for scanning applications.

To ensure that our components are ideally suited for your optical applications, our team of engineers designs them with the most appropriate materials. Our experience has shown that the following materials are particularly effective for projects in the optical industry.