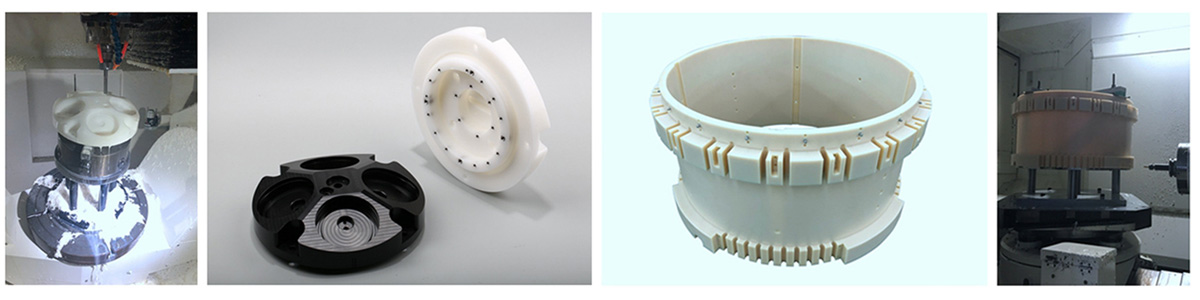

Precison PET & PEEK CNC Milled And Turned Parts for Optical Devices

Dedasun has a reputation for successfully machining the plastic other producers prefer not to handle. Customers can confidently design with new materials, secure in the knowledge that Dedasun can machine even the most exotic, PEEK Materials for a quality, cost effective result.

Products

Products DETAILS

Precison PET & PEEK CNC Milled And Turned Parts for Optical Devices

Dedasun has a reputation for machining quality parts from PET&PEEK plastic. We can machine intricate parts on our CNC machines and CNC turning centers.

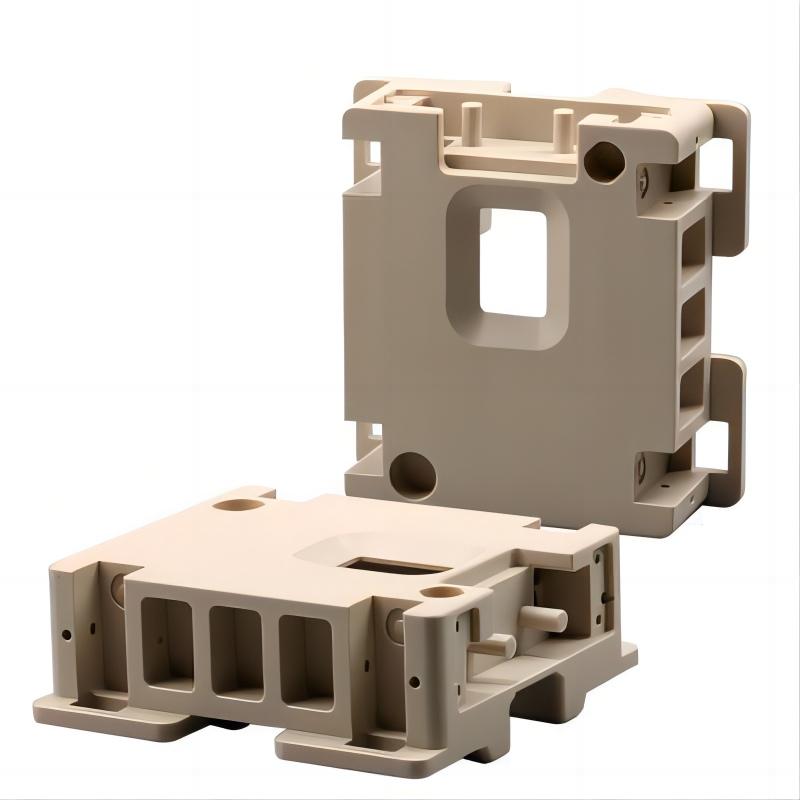

PET & PEEK Plastic non-standard parts fabrication services for small, large and heavy components.

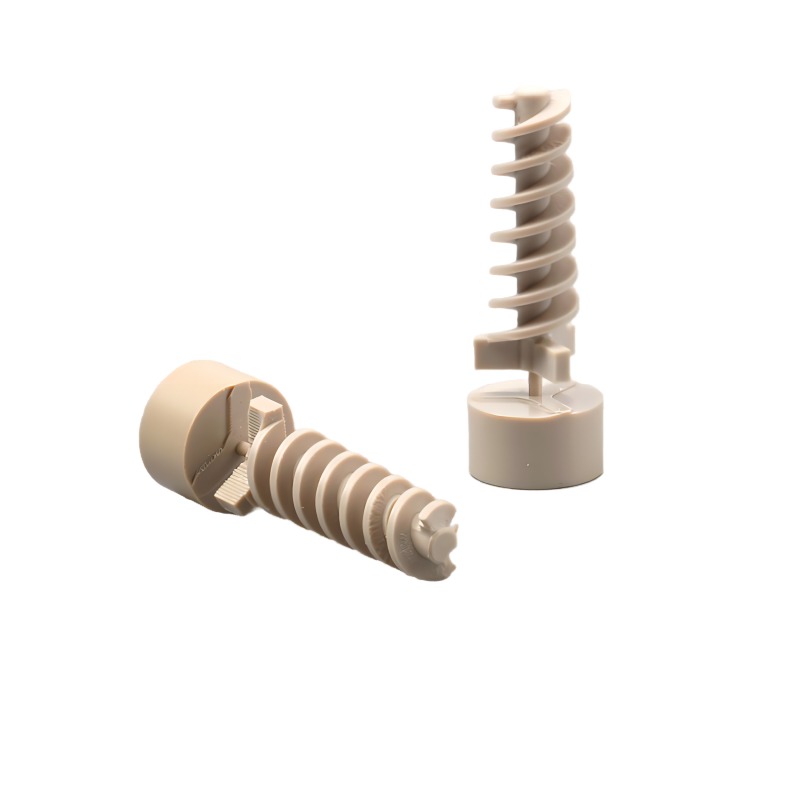

Polyetheretherketone (PEEK) resin is a special engineering plastic with excellent performance. It has more significant advantages than other special engineering plastics. It has high temperature resistance of 260 degrees, excellent mechanical properties, good self-lubricating property and chemical corrosion resistance. , flame retardant, peeling resistance, wear resistance, not resistant to strong nitric acid, concentrated sulfuric acid, radiation resistance, superior mechanical properties can be used in high-end machinery, nuclear engineering and aviation technology.

PEEK has a machining cost factor of 0.9 when compared to steel 12L14.

PET is a milky white or light yellow highly crystalline polymer with a smooth and shiny surface. It is resistant to creep, fatigue, abrasion and dimensional stability, low wear and high hardness, and has the highest toughness in thermoplastics: good electrical insulation, low temperature, but poor corona resistance. Non-toxic, weather-resistant, chemical-resistant, good water absorption, low acid resistance and organic solvents, but not soaked in heat-resistant water, not resistant to alkali.

PET has a machining cost factor of 0.8 when compared to steel 12L14.

PET Machining Industries & Applications

- ▶ Gears

-

▶ Bearings

- ▶ Bushings

- ▶ Sprockets

- ▶ Electronic components

PEEK Machining Industries & Applications

- ▶ Bearings

-

▶ Bushings

- ▶ Pump components

- ▶ Medical implants

- ▶ Aerospace components

View more plastic machining parts on our Product Page

Dedasun has a reputation for successfully machining the plastic other producers prefer not to handle. Customers can confidently design with new materials, secure in the knowledge that Dedasun can machine even the most exotic, PEEK Materials for a quality, cost effective result.

- ▶ High grade plastic materials : PI ,PAI ,PEEK ,PCTFE , Ceramic ,etc;

- ▶ Medium grade plastic material : PEI, PPS, Unilate, PVDF ,etc;

- ▶ Commonly used cost-effective plastic materials : ABS, PMMA, PC, PTFE, PET, UPE, PA6, POM, UHMW, PP, PVC , PU etc;