Precision Sheet Metal Fabrication 101: Your Basic Knowledge Guide

Upload Time:

Feb 24, 2024

In this guide, you will find all information about precision sheet metal fabrication. Whether you want to learn about the process, tools, benefits or applications; all information you are looking for is right here.

What Is Precision Sheet Metal Fabrication?

Precision in sheet metal fabrication refers to highly-accurate processes requiring tight tolerances, consistency and paying attention to details.

Therefore, whether you are cutting, forming, welding or applying finishing surface finishing, the processes must be very accurate.

Precision Vs. Standard Metal Fabrication

Ideally, the two processes are virtually the same. However, precision metal fabrication puts more emphasis on accuracy and consistency.

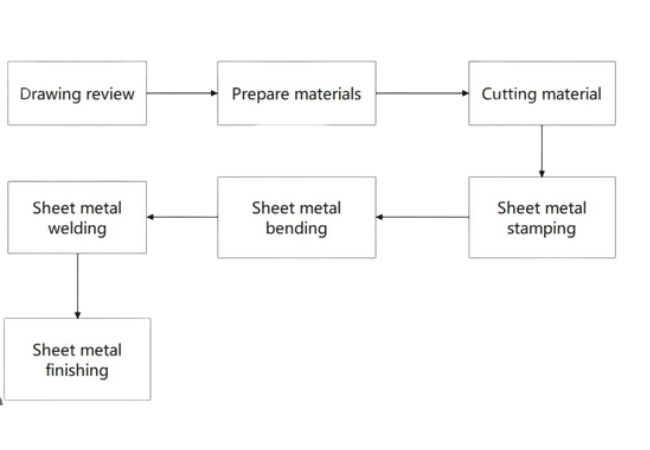

Sheet Metal Fabrication Process

Sheet Metal Fabrication Process

As a result, it is different from standard metal fabrication with regards to:

- Type of sheet metal fabrication machines – here you will use automatic machines using dedicated software to control various operations

- The process is suitable for complex parts or with intricate shapes and designs

- Cost of precision metal fabrication is slightly high

Finally, it is important to note that not any company can handle this metal fabrication process. You must work with highly trained, reputable and experienced precision sheet metal fabricators.

Why Precision Matters In Sheet Metal Fabrication

The word precision is often “thrown” around in sheet metal fabrication industry. It is because accuracy critical for most components.

Some of the main reasons why you should consider precision in sheet metal fabrications are:

- You can achieve tight tolerances

- With high accuracy, all your components will be identical even for mass production

- Reduces possibility of secondary operations which may add on unnecessary costs

- Allows for easier repeatability

- Reduces sheet metal parts production costs

Precision Sheet Metal Fabrication Application

Although you can use the metal fabrication technique, there are some variables you should consider. Take for example, if you are handling the following scenarios:

- Parts require high level of accuracy, dimension consistency and tight tolerances

- When fabricating complex sheet metal parts and components

- When you want to minimize wastages especially for very expensive sheet metals

- Application where safety is a critical factor

- Large run production at relatively low cost

The fabrication technique is suitable for virtually all industries including:

- Aerospace

- Biomedicine

- Home appliances

- Robotics

- Chemical processing

- Oil and gas industry

- Automotive industry

- Electronics and computers, etc.

Precision Sheet Metal Fab Techniques

There are many techniques you can use in sheet metal manufacturing process. Whichever process you opt for, it must guarantee accuracy and consistency.

Again, like the normal sheet metal fabrication process, the key stages still remain the same. That is, you will:

Choose Suitable Sheet Metal

You can fabricate nearly all sheet metals including copper, steel alloys, aluminum, titanium, aluminum, brass, etc.

Cutting Sheet Metal

Since we want very tight tolerances and accuracy, you will use computer numerical control (CNC) machines.

CNC cutting machine guarantee high level of accuracy and consistency. You may consider any of the following options:

- CNC plasma cutting machine

- CNC laser cutter

- CNC router machines

- CNC punching machine

In today’s precision metal fabrication, CNC laser cutting is a popular technique. Laser cutting is suitable for nearly all metal alloys including brass, steel, copper or aluminum.

The best part, you can achieve tight tolerances which may vary from +/- 0.03 to 0.007 inches. In fact this is the best you can get for precise sheet metal parts and components.

In a nutshell, the sheet metal cutting tool must be very accurate and reliable.

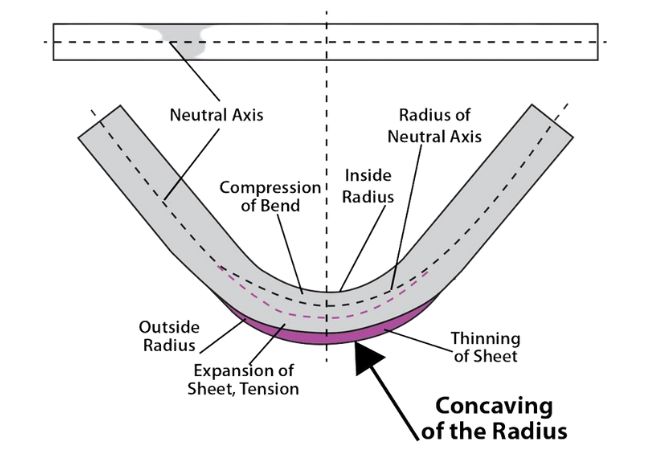

Forming Sheet Metal Parts Accurately

Precision sheet metal bending is important. You should have seamless curves and bends. This way, you will get high quality parts.

In today’s precision sheet metal fabrication, CNC press brake is perfect equipment.

With precision ground tooling, you can achieve very tight tolerances.

Of course there are many sheet metal bending techniques. However, the degree of accuracy vary broadly. For example, coining and bottoming are more accurate than air bending sheet metal.

Whereas CNC press brake bending sheet metal is the most accurate.

Other forming process may include stretching, tamping, deep drawing, etc.

Welding Sheet Metal Parts

Again, you will focus on precise sheet metal assembly techniques. That is where precision welding play a significant role.

In precision welding, you will apply the weld in a controlled manner. In fact, the dimensional tolerance should be within +/- 0.2mm.

Over the years, TIG welding is popular for precision sheet metal welding. However, TIG welding sheet metal is time consuming.

Of course, you can use other sheet metal welding techniques such as shielded metal arc or gas metal arc (MIG).

However, you must work with experienced welder. Maybe you can refer to them as precision sheet metal welder.

Remember, welding is just one of the many ways of joining sheet metals. Depending on the sheet metal parts you wish to join, you may use:

- Riveting

- Nut and bolts assembly

- Screws assembly

- Soldering and brazing

- Using metal adhesive

During precision sheet metal manufacturing process, you will adopt techniques that guarantee accuracy and consistency.

Applying Necessary Surface Finish

Once you have the precise sheet metal part and component, you will then apply the necessary surface finish. This can be:

- Painting

- Anodizing

- Electroplating

- Polishing

- Sandblasting, etc.

In short, it is important to note that precision sheet metal fabrication is not limited to the processes above.

However, we can summarize the guiding principle as:

- Removing specific work piece from the main sheet metal (cutting)

- Deforming the work piece to desired shape

- Joining or assembling parts to get the shape you want

In each process, the procedure must be very accurate.

How To Guarantee Precision And Accuracy In Sheet Metal Fabrication?

There are a number of steps that will help you get very accurate sheet metal parts. For instance, considering these key points will be helpful:

- Work will high trained, and experienced precision sheet metal fabricators

- There should be a dedicated quality control team to inspect and verify the dimension, and surface finishing

- In the technical drawing, label every dimension accurately

- Use modern CNC machine and if possible

Conclusion

Precision in sheet metal fabrication implies you have accurate parts wit very tight tolerances. However, the process may not be viable for all sheet metal parts fabrications.

This is due to the initial cost involved.

So, you must assess the situation at hand before venturing in the sheet metal fabrication technique.

Relevant News