How to Reduce Sheet Metal Fabrication Cost

Upload Time:

Feb 24, 2024

There is no specific formula to reduce the cost of fabricating sheet metal. However, the following measures will reduce the total cost

Use Sheet Metal Fabrication Price Calculator

It will help you determine sheet metal fabrication cost estimation. With this information, you can adopt special measures that cut costs.

Flexibility in Sheet Metal Part Design Is Critical

Remember, changing two or three dimensions can significantly impact the total sheet metal fabrication cost.

Additionally, adopting in-house tooling can also help reduce fabrication costs.

Work Closely With Experienced And Reputable Sheet Metal Fabricators

A sheet metal fabricator with experience will help you reduce the over cost. They can help redesign, choose appropriate fabrication techniques, suggest alternative finishing, etc.

Other ways to reduce costs are:

- Use readily available sheet metals

- Go for simple designs where you can

- Always conduct design for manufacturability (DFM)

- Finishing options should cut cost

- Go for tight tolerance when necessary

Although websites like a homeowner may give sheet metal fabrication prices as $100 for low and $5,000 – they may be misleading.

Contact the sheet metal fabricator if you want accurate estimations.

Chapter 1: Sheet Metal Fabrication Machine

There are many sheet metal fabrication machine designs.

However, you may require specialised machines whenever there are specific process requirements, such as precision sheet metal fabrication. In this case, you will use CNC machines for sheet metal fabrication.

Some of the most common machines for fabricating sheet metal include:

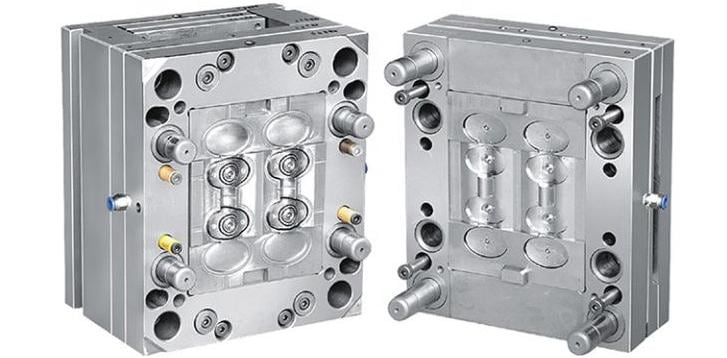

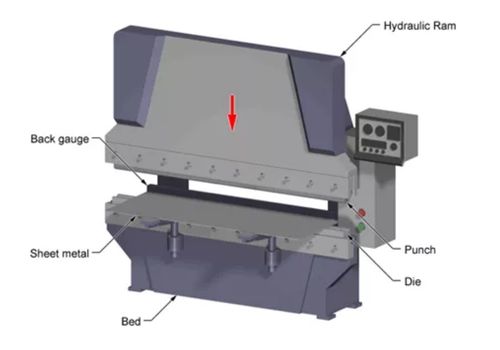

Sheet Metal Beding Machine

Sheet Metal Beding Machine

Figure 10 Sheet metal bending machine

- Cutting machines such as laser cutting machines, Waterjet cutting machines, plasma cutters,

- Sheet metal banding machines – press brakes help in the sheet metal bending process

- Plate rolling machines – you will use the equipment to form conical or round sheet metal parts

- Shears – they help cut sheet metal sheet

- Punching machine – turret punching help in the sheet metal punching process

- Lathe machines can perform various functions such as drilling sheet metal, boring sheet metal, spinning sheet metal, and cutting sheet metal, amongst others.

- Milling machines – they remove unwanted sheet metal parts

- Welding machines – you will use the equipment to join different pieces of sheet metals

- Riveting machine

In short, every metal fabrication process will require a unique machine. Therefore, the metal fabrication machine types depend on the fabricators’ capability.

Chapter 2: Sheet Metal Fabrication Calculator

A sheet metal fabrication calculator is an interactive software for estimating various parameters when fabricating metal parts.

Currently, no standard sheet metal fabrication calculator is 99.9% accurate. The available calculators only give estimated values.

Sheet metal bending calculator is the most popular software in the industry. They come in different configurations.

With this calculator, once you input sheet metal thickness and inside radius, you can get the following:

- K-factor

- Y-factor

- Neutral axis offset

Again, once you input the sheet metal bending angle, you will get:

- Bending allowance

- Arc length

Additionally, among the other sheet metal fabrication calculators are:

- Bend allowance calculator

- Bending spring-back calculator

- V-bending and wipe force calculator

Interestingly, developers are working on a sheet metal fabrication cost calculator. Well, I recommended contacting a sheet metal fabricator for accurate cost estimates.

Chapter 3: Sheet Metal Fabrication Material

There are many types of sheet metal types and grades. Typically, the sheet metal fabrication material type will depend on the intended application.

Let’s look at some of the most common options:

Aluminum Sheet Metals

Aluminum is known for its lightweight and excellent strength. It is suitable for low-temperature applications.

Additionally, you can quickly fabricate aluminum sheet metal.

Steel Sheet Metal

Steel sheet metals are available as stainless steel, galvanized steel and carbon steel. All the steel alloys are easy to fabricate.

Besides, they form excellent sheet metal parts and components. They have excellent mechanical and chemical properties.

Magnesium Sheet Metal

Fabricating magnesium sheet metal will be the best option where you need stiff and low-density material.

Brass Sheet Metal

Brass sheet metal is known for being lightweight, having high tensile strength and excellent corrosion resistance.

Bronze Sheet Metal Fabrication

Bronze sheet metal is a low melting point material. However, it is stronger than copper sheet metal.

Copper Sheet Metal

Copper sheet metals are electrically conductive and corrosion-resistant. They are easy to fabricate.

Titanium Sheet Metal Fabrication

Titanium sheet metal is easy to fabricate. It can withstand extremely high temperatures.

Additionally, they have a good weight ratio, toughness and excellent corrosion resistance.

You can fabricate virtually all sheet metals.

However, you should know the physical and chemical properties before fabricating any sheet metal. With this information, you will choose suitable fabrication techniques.

Chapter 4: Sheet Metal Fabrication Application

Fabricated Sheete Metal Part

Fabricated Sheete Metal Part

Today, every industry uses at least one or two sheet metal fabricated parts.

Whether you want small, large, simple or complex parts – fabricated sheet metal parts have dominated virtually all industries.

Let’s look at some examples:

- Aerospace industry – aeroplane body parts

- Building and construction – roofing parts, doors, gutters, windows, etc.

- Agricultural – irrigation equipment, storage cabinets,

- Electronics – electrical enclosure, electronic casing, brackets, phone parts

- Oil and gas industry – storage tanks, stairs, etc.

- Medical sector – medical instruments, plates, implants,

- Automotive industry – vehicle body and related parts

You can make virtually anything by fabricating sheet metal.

Chapter 5: How to Check the Sheet Metal Parts Quality

Quality inspection and control are essential aspects in fabricated sheet metal parts.

Typically, the quality inspection process varies depending on the sheet metal part you are fabricating. Remember, every industry has unique quality standard specifications.

For example, quality requirements for welding aeroplane body parts differ from steel doors.

Let’s look at some vital quality inspection criteria in sheet metal parts:

- Check sheet metal material quality – you can use the cupping test, tensile test, fatigue, hardness test, etc.

- Examine sheet metal part thickness

- Ensure the fabrication process adheres to acceptable standards – for instance, ISO 1461 for hot dig galvanization, ASTM standards for sheet metal welding, etc.

- Surface finish quality matters – check for any defects or possible inconsistency

- Ensure the joints are as per specification

- Check the sheet metal fabricating company quality procedures

- Non-destructive testing such as AS9102 First Article Inspection Report (FAIR) and Geometric Dimensioning and Tolerancing (GD&T) are also critical

- Review third-party quality inspection report

Quality testing should also focus on fabrication equipment and processes. This way, you can easily predict the quality of the final sheet metal fabricated part.

Chapter 6: Dedasun Capabilities Of Sheet Metal

Over the years, Dedasun has remained a global leader in sheet metal fabrication parts. Through our experienced engineers and technicians, we offer unlimited possibilities in the sheet metal fabrication industry.

At KDMFAB, fabricate small, large, simple and complex sheet metal parts. We can handle a range of fabrication processes for sheet metal, such as:

- Sheet metal cutting – a range of cutting options such as shearing, Waterjet, plasma and laser cutters are available

- Sheet metal welding – you can use robotic welding for high consistency and accuracy. We use laser welding, MIG welding and TIG welding.

- Sheet metal forming – our brake bending machine guarantees a high level of accuracy

- Sheet metal shrinking – Dedasun metal shrinking machines guarantee zero dents

With the CNC machines, Dedasun ensures high precision and repeatability.

The Dedasun team will help you choose the best options for sheet metal surface finish.

Talk to us now for competitive prices on fabricated sheet metal parts. We support OEM clients too.

Relevant News