7075 Aluminium – The Ultimate Guide

Upload Time:

Feb 25, 2024

In this guide, you will get to know more about what 7075 aluminium is, its key elements of composition, its unique properties, its limitations, its advantages, its applications, and more. Let’s delve in to know more.

What is 7075 Aluminium?

7075 aluminium or AA7075 is an alloy which is made up of zinc being its main element and aluminium alloy which is heat treatable.

7075 Aluminum

7075 Aluminum

It is sold with different names known as its trade names which include;

- Ergal

- Zicral

- Fortal Constructal

AA7075 has amazing mechanical features and is high in strength, tough, and can resist corrosion in higher levels.

It is one aluminium alloy that is used more for structural applications that require more stress.

Key Elements in 7075 Aluminium Composition

7075 alloy has 3 main elements of its makeup and other secondary elements. Below is a list of these elements that come together to make aluminium:

- Zinc 5.6 – 6.1%

- Copper 1.2-1.6%

- Magnesium 2.1-2.5%

Below are the secondary elements of composition. They are:

- Iron 0.5%

- Silicon 0.4%

- Manganese 0.3%

- Titanium 0.2%

- Chromium 0.18-2%

- Others elements

How Tempering Affect Aluminium Alloy 7075 Mechanical Property

Tempering of 7075 plays a major role in determining the tensile strength of the alloy.

Let’s look at some tempering options available:

| 7075 Alu Grade | Key Features or Properties |

| 7075-0 |

· When un-heat treated, it comes with at most 280 MPa of tensile strength.

· Yield strength of 140 MPa maximum. · Its elongation ranges from 9-10%. · This type resists corrosion greatly. · Has the finest profile where strength is concerned. |

| 7075-T6 |

· It comes with 510-540 MPa ideal tensile strength.

· Its ranges from 430 – 480 MPa yield strength. · It has 5-11% where failure elongation is concerned. |

| 7075-T651 |

· Its full tensile strength stands at 570 MPa.

· Its yield strength stands at 500 MPa. · You get 3-9% of failure elongation with this type. · Thicker plates will show strengths that are low. |

| 7075-T7 |

· This temper comes with the ideal tensile strength of MPa.

· Its yield strength is at 435 MPa. · Its failure elongation stands at 13%. · T7 temper generates microstructure of about eta precipitates. · Its susceptibility to corrosion and cracking is less. · T7 is just like T73. |

| 7075-RRA |

· Its full name is Retrogression and Reage temper.

· It is a heat treatment tempering process achieved in stages. · The stage begins with T6 temper sheets then is continued to become like T7. |

Physical Properties of 7075 Aluminium

The density of this aluminium grade is 2.810 g/cm density. Other physical properties include:

- It is very light.

- It is very strong and this makes it easier for it to withstand any form of stress.

- Due to copper presence in this alloy, its susceptibility to corrode is heightened. This is needed to ensure AA7075 is a material that is strong, but still workable.

Advantages of 7075 Aluminium

- High level of strength.

- Fatigue strength is fair.

- It has high level of strain and stress resistance.

- When polished, it has the finest finish.

- Comes with heat treatable features.

Limitations of Aluminium 7075

- Its cost is quite high.

- It has poor weldable features.

- Resists corrosion lesser when compared to other alloys.

- Averagely machinable.

- It is prone to cracking.

- It has poor formability

- it has poor workability

Aluminium 6061 vs 7075 – Unique Differences

These factors below will definitely be what makes the differences of these two alloys clear:

- Chemical composition and alloy series.

- Fabrication.

- Mechanical Properties.

- Applications.

Aluminum 6061 Properties

Aluminum 6061 Properties

The details are below:

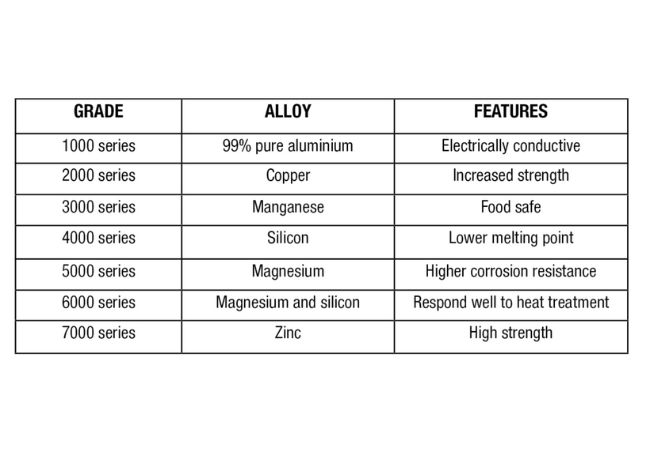

Chemical Composition and Alloy Series.

- The very initial disparity between these two aluminum alloys is identified when you check out their numerical designations.

- 6061 has more silicon content and 7075 has higher amounts of zinc.

- Both alloys come with some amount of magnesium. However, 6061 has a reduced amount compared to 7075.

- The copper amounts in 7075 is higher than 6061 alloy.

Fabrication

- 6061 has much more edge when compared to 7075 where fabrication is concerned.

- 6061’s low tensile strength and hardness makes machining easier with it compared to 7075.

- You can form 6061 easier than forming 7075.

- Welding 6061 is effortless while AA7075 isn’t weldable. When 7075 is welded through different treatment methods, its probability to crack is higher.

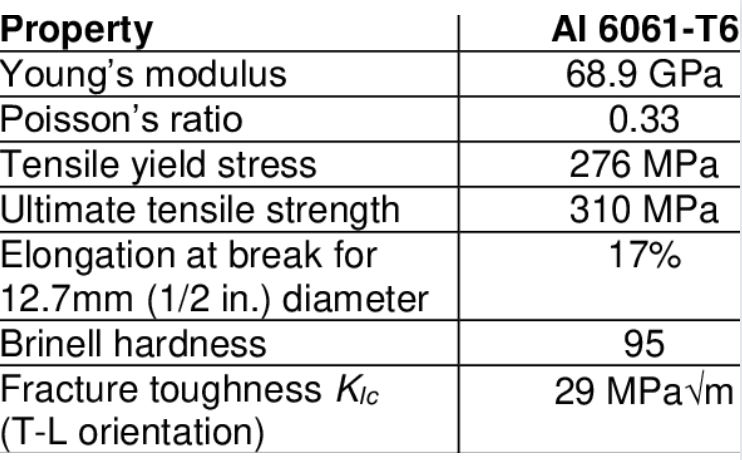

Mechanical Properties

Both alloys are heat-treatable. This is why their properties cannot be compared to perfection without considering the heat treatment type.

Applications

Both alloys can be used in making the following:

- Bikes

- Building construction.

- Aerospace parts.

- Industrial tooling.

Although they are used for the above, there are some disparities between the two in the specific areas of use.

- 6061 is famous in use where higher ductility is required whiles 7075 is used more in the aerospace industry to make rods and gear.

- Where bike components are concerned, some riders love 7075 for higher strength levels it represents compared to 6061.

- 7075 is used more in the areas of molds and industrial tools compared to 6061.

- With the finest forming features 6061 has, it is used more for tanks while 7075 is not immediately considered for such forming applications.

Forming & Fabricating Alu 7075

7075 Aluminium Welding

- 7075 comes with a material that is harder and higher content of zinc. This makes it not ideal to welding and forming.

- In conditions where it has been annealed, 7075 can easily be formed and go through heat-treatment, if there is the need.

Machining 7075 Aluminium

To know the machinability of any metal or material, it has to be measured as to how it reacts to different machining methods such as die-casting, milling, cutting, etc. It has average machinability.

Forms Alu 7075 Alloy Exist

In most industrial setups, this alloy is available as:

- 7075 Aluminium Sheet

- Aluminium 7075 Plate.

- 7075 Aluminium coil.

- Aluminium 7075 checker plate.

- 7075 Aluminium foil.

- 7075 Aluminium colour-coated foil.

- 7075 corrugated plate

All the above forms are designed or made to come in different sizes and weights. This is done to ensure various user needs are met.

They are also designed to come in different colors, based on the form you choose.

Alu 7075 Alloys Composition

Alu 7075 Alloys Composition

Factors Determining 7075 Aluminium Price

The price of 7075 will be determined by quite a number of factors. So, you do not need to consider the highest prices to be the best, alone.

Some of the factors are:

Present Demand and Supply

During your time of purchase, the demand of the alloy will be what decides the cost. So, you definitely will need to have the market demand and supply checked. This will help you know for sure the cost.

Material Cost

7075 alloy is composed of varied elements. So, when the elements on the market are scarce or are highly priced, it means, it affects the manufacturers of this alloy.

Shipping and Labor Costs.

Even though local shipping costs might be reasonably priced, imports are never the same. When you ship outside or buy from outside of your country, the costs will be higher.

Currency Shifts or Fluctuations.

The currency changes and fluctuations can affect the cost as well.

Form being Purchased.

There are times when the form or type of 7075 alloy you are buying or need can lead to its cost being higher or lower.

Quantity being purchased.

The quantity you want to buy can affect the total price of 7075 too. The more you are buying, the higher your chances of getting some discounts.

Supplier you are Buying from.

Different suppliers provide you with different price tags. So, this also coming together will affect the price as well.

Most of the other factors that can affect the price of 7075 alloy are political issues, economic issues worldwide, etc.

Different Finishes on 7075 Alu Alloy

Where 7075 Alu is concerned, the finishes that they come with will always differ. So, you need to know these to ensure the right look and protection levels are achieved.

Some common finishes include:

Powder Coating.

This unique finish provides a very durable and thick finish that also will resist scratches, corrosion, and fading.

It comes in different shades. Due to this, you are able to make your ideal choices.

Wet Painting

This type of finish is famous because it ends up creating a durable, and safe layer on the metal surface. It helps in resisting corrosion or scratches.

It is the cheapest finishing type. It provides the fundamental protection level against scratches and corrosion. However, it doesn’t come with durability levels that anodizing and powder coats come with. It also comes in different colors to choose from.

In addition to this, you can also anodize or polish aluminum surface.

Where to Use Aluminium Alloy 7075

You can use 7075 Alu in many applications such as:

- Gears and shafts

- Worm gears

- Aircraft fittings

- Missle parts

- Aerospace or defense

- Regulating valve components

- Bike frames

- Sprockets for vehicles – all terrain, etc.

Conclusion

From this article, it is clear that 7075 is a strong alloy with some fine heat treatable features. This means, being able to choose the right forms for your various projects and knowing the right finishes to use will pay off.

Make the right decisions to buy from the right suppliers for quality all the time.

Relevant News