Laser Engraving on Metal – The Guide for Beginners & Experts

Upload Time:

Feb 25, 2024

Understanding the best way to laser engrave metal is key to your engraving business. With this knowledge, you can choose a suitable material, and laser engraver machine. It will also help you evaluate whether the business will be viable or not. This guide will help you become an expert in this decorative industry – how to engrave using laser machine.

What is Metal Laser Engraving?

The process of engraving metals allows for the marking of text, logos, numbers, images, and other items. Laser beam remover very tiny material parts, leaving a permanents mark.

How to Choose Metals for Laser Engraving Process

When you want to laser engrave on metal, the first step is choosing suitable material. Let’s look at some common materials:

Laser Engraving Stainless Steel

Stainless steel can be engraved using a:

- CO2 Laser

- IR Laser

- Diode Laser

- Fiber Laser

Regardless of the fact that stainless steel is significantly complex to engrave, it offers a variety of benefits. Stainless steel is:

- Extremely robust

- Resistant to corrosion

- Impervious to moisture

At 50 – 65 IPM and a 600 DPI resolution, you can engrave stainless steel efficiently. Of course, this will be practical when using between 90 and 95% of the power source.

Laser Engraving Steel

It is without doubt that steel is utilized in our routine way of life. Steel is used to manufacture divergent commodities and goods.

Lasers can also be used to engrave steel. Permanent inscriptions are constantly made to specify the component or maker.

The engraving machine operates at a speed of approximately 50-65 IPM and a precision of 600 DPI.

While drawing 90-95 percent of the electrical supply for the optimum engraving.

Laser Engraving Aluminium

You can choose anodized or polished aluminum for laser engraving awards and other forms of decorations.

Machined aluminum can be used for industrial purposes, corporate branding, and circuit boards. All forms of metal, from coated aluminum to raw aluminum, can be engraved permanently and with excellent contrast.

Laser engraved aluminum parts are exceptionally resistant to high temperatures and other surface treatment techniques such shot blasting. For best results, the engraver runs at speed of about 60 – 80 IPM and a 600 DPI resolution while using 80 -90% of the power source.

For aluminum, you may choose:

- Fiber laser engraver – it remains a popular option for laser engraving Aluminium. You can engrave durable marks with high contrast.

- CO2 laser engraver – To laser engrave aluminum, it is important to apply special coating. The coating will prevent metal from reflecting wavelength from the CO2 laser engraver. Usually, the reflected wavelengths can damage the machine.

Laser Engraving Copper

Copper wires, cooking pots, auto parts, and other products can have laser engravings etched for identification.

Laser Engraving Silver

Silver can be engraved similarly to gold. Magnificent gems, accolades, awards, and other possessions are susceptible to laser engraving.

Laser Engraving Gold

Gold gems, accolades and incentives can be laser engraved. Trophies, jewelry, awards, etc. can be engraved.

Laser Engraving Titanium

Titanium is also critical in laser engraving. It is used in the manufacture of a variety of products such as ornaments, prosthetic device, pharmaceutical tools, and planes.

Engravings are used as part identification and personalization of items made of titanium.

For the best engraving, the engraver runs a speed of about 50 – 60 IPM and an 800 DPI resolution while using a 100% of power source.

Laser Engraving Brass

The engraver should operate at a speed of 60 to 80 IPM with a resolution of 600 DPI while consuming 80 to 90% of its power source for optimum engraving.

You can easily engrave brass to any pattern or design.

How to Prepare Metal for Laser Engraving

You should make sure that the surface is spotless before applying. Make a mark on the edges of the surface you intend to with some masking tape.

On the metal surface, uniformly apply the engraving spray. Spray two or three applications of dry lube, letting each layer dry completely before applying the next.

Remember, you should treat highly reflective surfaces. Take for instance, aluminum tend to reflect wavelength from CO2 laser machine. The phenomena is always detrimental since it can damage the laser machine.

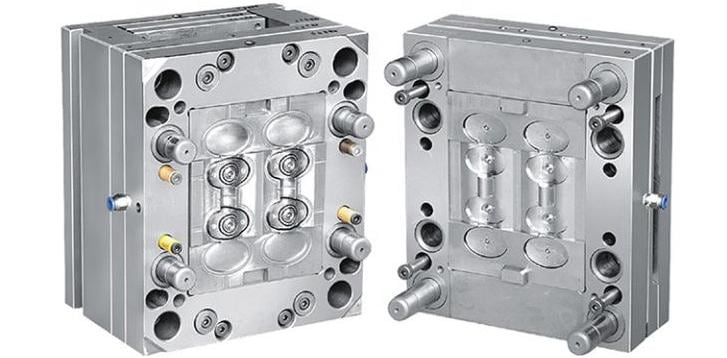

Laser Engraving Metal

Laser Engraving Metal

How to Choose a Metal Laser Engraving Machine?

Choosing the appropriate laser engraving machine can be challenging especially when it is your first-time using laser engravings on your project. It is vital that you make significant considerations in the selection process. They include;

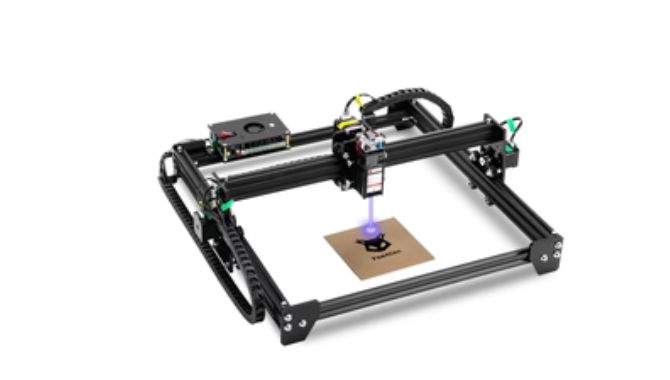

Small Laser Engraving Machine

Small Laser Engraving Machine

Output Power Source

The power requirement for a machine are critical in identifying which material to use and of what thickness. Hard metals have a demand for a 40W to 150W laser machine power rating. In most straightforward applications, laser engraving machines with the power rating of between 20W to 50W are used.

Additional Technology

The choice of machine to use should also factor in the additional technology that can be incorporated in the machine. The technologies involved help in creating exceptionally high quality product engraving.

Most laser engraving machines are advantageous. They have simplified the engraving process and give better laser engraving results.

Other vital aspects you must consider include:

- Ease of using the laser engraving machine

- Availability of replacement parts

- Cost of buying the machine

- Production capability

- Go for only reputable brands of laser engraving machines

How to Laser Engraving in Metals Work

A 60w fiber laser will engrave most metals. Also, a perfect alternative to this has always been diode laser.

But, even at this stage, it is important to note that:

- Whenever you are engraving tough metals, expect to use laser machine with high power.

- Laser engraving efficiency reduces for highly reflective or glossy metal surfaces. Such surfaces reflect the useful laser beam. In the worst case scenario, they may damage the laser engraving machine.

With that in mind, let’s quickly explore steps in metal laser engraving process:

Step 1: Select the Laser for Engraving

Laser Engraver Machine

Laser Engraver Machine

There are various sorts of lasers, and it is crucial to pick the proper one for your application based on its wavelength and laser source.

Step 2: Design Pattern you Want to Laser Engrave on Metal

There are many design software such as LightBurn, Inkscape, and CorelDRAW, just to mention a few.

With these software, you can make good designs.

Furthermore, you can also use a nesting software. The software can help cut cost during the design and subsequent laser engraving process.

Step 3: Configure Laser Engraver for the Ready for the Process

Configuring laser machine ready for the engraving process can be a challenging task. Here are best tips that will help:

- Laser power – choose power settings depending on metal you wish to engrave

- Configure laser engraving speed – it is a critical elements that effects the depth of engraved sections. Additionally, it will affect the contrast.

- Ensure the laser beam is focused – adjust machine setting to ensure it can focus on specific metal section you want to engrave

- Use suitable gas assist – it helps to blow away cut section thereby leaving clean section. This will speeds up the laser engraving process.

- Determine the number of pass – when the engraving requires deep cutting, you must be careful to avoid discoloration. Remember, this can also cause overheating metal section.

Once you configure all these, you will conduct a test run. Through test run, you will examine how the engraving process works. Additionally, you will examine quality of the final laser engraved part before mass production starts.

Step 4: It’s Time to Engrave Metal Part using Laser

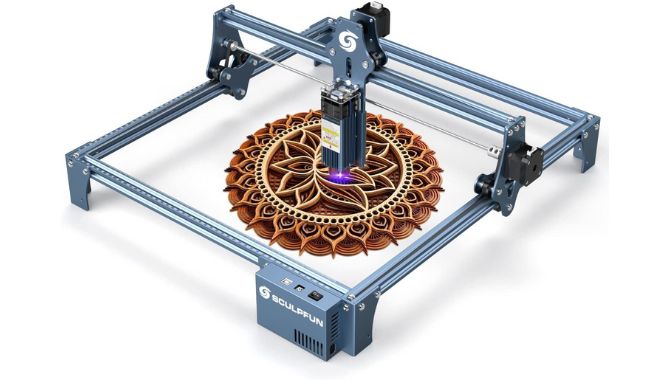

Laser Engraving Metal Part

Laser Engraving Metal Part

After conducting test run with the right settings, it is now time to begin the laser cutting process.

At this stage, the process involves:

- Cleaning the working table and work piece – a clean surface will improve efficiency and part quality

- Set up the metal ready for engraving and secure it appropriately

- Put the laser machine in position, load the design in the machine software

- Once the design is ready, you can begin engraving the final pattern. Remember, laser engraving is an automated process.

The laser machine will automatically engrave the metal, leaving a clear pattern or design.

Note: As you use laser machine, ensure you adhere to the manufacturers safety rules and operation procedures.

Benefits of Metal Laser Engraving

There are many reasons why you should consider starting laser metal engraving business. Let’s have a quick overview:

Longevity

Since its inception, engraving has been admired for its enduring quality. People used to engrave their personal belongings, weapons, and pretty much everything else they could get their hands on even before the invention of lasers.

Several of these carvings are still visible today because they have withstood the test of time and the ravages of daily use. Because engraving removes some of the material off the surface of the item, it is different from other types of item personalization.

Speed and Efficiency

It can produce the necessary completed product with a high level of efficiency in a very short amount of time, this clear speed advantage makes it a superior way of marking. Because time is money, the laser engraving technique is incredibly cost-effective due to its speed and efficiency.

Easy to Use

Once you upload the design you want to engrave, and configure the machine. All the other processes are fully automated.

High Precision

Laser engraving has a high degree of precision as a technique. Even the smallest material surfaces may be precisely engraved with complex designs thanks to a resolution of up to 39 pixels per millimeter.

Minimal Maintenance Required

Due to the complete lack of mechanical wear and tear caused by the process of laser marking, the laser engraver has a long operational life.

Apart from routinely cleaning the focus lens, there is no further maintenance needed.

Limitations of Laser Engraving on Metals

As you choose laser engraving metals, there are certain challenges you will deal with. Take for example:

Fewer Applications

Laser engraving are less versatile in applications since not all metals can be engraved when compared to laser etching.

Material Wastage

Due to vaporization of metals, more resources are used in laser engraving.

Poor Energy Consumption and Time Use

Some materials require longer processing time accompanied by stronger laser power to engrave.

Applications of Metal Laser Engraving

Laser engraving on metal offer unlimited possibilities in today’s metal fabrication industry.

Some common applications include:

Laser Engraved Name Plate

Laser Engraved Name Plate

Laser Engrave Identification

You can engrave brand logos, Card details, identities, tracking systems, QR codes, and other details on metals. The permanent label that is never erased tends to make identification substantially straightforward.

Signage Engraving

Today, we have many laser engraved signage. It is because they are durable and offer permanent markings.

Nameplates Engraving

There are featured nameplates on doors and tables that are engraved using metal laser engraving machines.

Creating Jewelry by Engraving

Personalized gift products can be manufactured through laser engraving. On necklaces, wristbands, timepieces, and ornaments, you can engrave messages, inscriptions, occasions, or anything else you like. Such customizable gadgets seem to be highly desired right now.

Trophies Engraving

You can engrave team names, trophy title, or any other graphic. Moreover, priceless competition awards like silver or gold medals can be engraved.

Creating Gifts by Engraving

The laser may be used to indelibly label whatever surface bearing initials, anniversaries, trademarks, as well as other text. Most customers prefer to give their family and friends these individualized gifts.

Branding via Engraving

The company’s product can have designer labels, emblems, Passcodes, locations, and other features embossed on it.

Marketing Materials Engraving

In the corporate domain, commodities are offered out as gifts to advertise brands. Plated cards, medallions, stationery, and other accoutrements can be in their custody.

Clearly, when it comes to metal laser engraving applications, there are numerous options available at your disposal. In fact, it plays an integral role when making custom parts.

FAQs on Laser Engraving on Metals

What Causes Color Change in Metal Laser Engraving?

It is all-natural; you don’t need to use any additional ingredients or coloring agents. As color changes are dependent on both the metal and the laser’s power, they are not particularly vivid. Oxidation leaves a distinctively colored coating on the metal that resembles colorful engraving. Moreover, the addition of a colored layer of oxide results in color variations.

Laser Engraving Vs. Laser Marking Metals; How to they Compare?

Laser engraving refers to the process on incising or removing microscopic particles using laser beam.

On the other hand, laser marking leaves discernable writings on portions’ surfaces with diminutive penetration.

Is Laser Engraved Metal Parts Permanent?

Laser engraving is permanent. All through the part’s operating time, laser engraving will be clearer to see than other straightforward element branding approaches. Laser engraving may endure non-abrasive processes like heat treating, powder coating, and e-coating.

How much Does Metal Laser Engraving Cost?

It may cost say USD 10 to more than USD.

There are many variable that determine the pricing here such as;

- Material type

- Complexity of the design

- Engraving depth

- Size of design

- Metal engraving company, etc.

If you want accurate quotation, contact trusted sheet metal fabricating company.

How Deep Can Laser Engrave Metal?

Metals can be easily cut by deep engraving to a range of several millimeters in comparison to ordinary laser engraving, which typically only penetrates a few microns.

Laser engraving can be as deep as 500 microns. Actually, it is common when using a shot-blast-resistant metal laser engraving technique.

What is the Recommended Wattage of Laser Engraving Metal?

While establishing the laser power, the usage surface and the techniques that will be applied must be considered as well. A 500W laser is not multiple times as swift as a 100W laser, but it is considerably faster.

Most deep engraving projects need a minimum of 100W. Deep engraving is also conceivable at lower power ranges, though it is not advisable since the engraving timeframes could be too extensive.

How does Laser Etching and Engraving Compare?

Let’s get to it:

| Variables to Compare | Metal Laser Etching | Metal Laser Engraving |

| Cutting depth | Shallow cutting depth – laser beam only melts the surface and does not go deep inside the metal. The depth is not greater than 0.001 inches |

Greater cutting depth since the process removes more microscopic material from the metal.

The laser beam can go as low as 0.125 inches. |

| Durability | Although the marks are durable, you cannot compare it to laser engraving. | The marks are very durable since laser beam cuts deep into the metal |

| Cost per unit area | Less costly | More expensive |

Although there are other aspects which may vary as much as quality is concerned, the above forms the main differences.

Conclusion

An ideal method for high-quality product finishing and branding is laser engraving on metals. The majority of designers and producers now use metal laser engraving due to its rising demand.

As a result, it can be used in a variety of industrial processes, commercial product labeling, and other applications. You should make use of this method if you want to distinguish your merchandise.

For all your laser engraving on metals requirements, contact Dedasun now.

Relevant News