Bronze Vs Brass Comparison Guide

Upload Time:

Feb 25, 2024

Whether you want to learn about the applications, mechanical, physical, or chemical properties of brass and bronze– you will find all information right here. It compares all vital details of these important metals.

What is Brass?

Brass is a metal with golden hue, which appears to be dull. The main alloying elements are copper and zinc.

You can add other components such as iron, lead, aluminum, silicon, manganese, or tin to improve it. Besides, you can mix these components in different ratios.

Brass Sheet Metal

Brass Sheet Metal

What is Bronze?

Bronze has reddish brown hue. The main alloying elements are tin and copper.

You can add other elements to improve its characteristics. These include silicon, zinc, phosphorus, and others.

Bronze Sheet Metal

Bronze Sheet Metal

Applications of Brass Vs Bronze

You can use brass in many areas such as:

Silicon Aluminum Bronze

This alloys consists of aluminum, silicon, and copper elements. It has a good corrosion resistance. In addition, the mechanical properties are also improved.

Its common usages include:

- Cams

- Parts that make landing gears

- Valve guides

- Hooks

- Assemblies for safety belts

- Machine parts that are forged

Tin Bronze

Adding tin to bronze will improve its strength. This alloy is both strong and hard thus can bear large loads and resist corrosion and wear. Besides, it can withstand the corrosive nature of salt water.

907 and 917 are examples of tin bronze alloy. You can use this metal to make:

- Bearings

- Parts of pumps

- Gears

- Bushings

- Marine applications

- Bridge turntables

- Bridge parts that move

Manganese Bronze

The alloy has excellent corrosion resistance and high strength.

For these reasons, you can find them in industries such as marine, gas, oil, and aerospace. It is strong and therefore suitable for heavy duty usages.

Common applications include:

- Load bearings

- Cams

- Bearings

- Gibs

- Parts that make landing gears

- Huge valve stems

- Strut bushings

Aluminum Bronze

Besides being strong, this bronze exhibits good resistance against wear and tear. Alloy 954 and 955 are some exampled you can find for this type. Aluminum bronze 955 is a durable non-ferrous type.

Furthermore, aluminum bronze 954 has impressive corrosion resistance properties. The common applications for these alloys include:

- Bushings

- Parts that make landing gears

- Spur gears

- Agitators

- Engines for airplanes

- Valve parts

- Worm gears

Machined Bronze Part

Machined Bronze Part

Brass alloys and their applications include the following:

Engraving Brass

This brass contains 1-2% of lead component. Engraving brass is also called C35600/C37000. It is suitable for engraving items like:

- Rims for appliances

- Meters for gears

- Hardware

- Clock parts

Yellow Brass

Yellow brass is strong. Besides, exhibit excellent resistance to corrosion. C260 is one example of yellow brass. Some of its applications include:

- Car parts such as thermostats, odometers, radiator tanks, electrical connectors, etc.

- Electrical parts like terminal connectors, reflectors, etc.

- Fasteners such as screws and rivets

- Industrial usages like heat exchangers, sound proofing units, etc.

- Plumbing

High Tensile Brass

This alloy is suitable for parts that will experience high magnitude of stress. Besides, it only contains manganese element. It is suitable for the following:

- Clamps for batteries

- Boat engines

- Wheels that handle heavy loads

- Axle boxes for vehicles

- Valve guides

Free Machining Brass

The C360 free machining brass is popular for a variety of applications such as:

- Terminals

- Injectors

- Nuts

- Weight balances

- Taps

- Pipe fittings

Red Brass

Red brass is soft. As a result, it is malleable. It contains 5% and 95% of zinc and copper respectively. Its primary uses include:

- Jewelry

- Door handles

- Ornamentals

- Grillwork

- Boat hardware

- Badges

Fabricated Brass Parts

Fabricated Brass Parts

Bronze vs Brass Corrosion Resistance

When copper mixes with oxygen, it will oxidize. Since bronze has copper, it may rust. This makes it develop a mottled patina. For this reason, it experiences minimal corrosion in seal water conditions.

Ever heard of bronze disease?

Well, when bronze makes contact with chlorine, this disease develops. For this reason, it can corrode easily.

Brass has an effect known as galvanic charge. This means it can easily withstand the effects of saline water. However, it can experience dezincification. This occurs when it loses zinc properties due to corrosion. The effect of this is that copper remain behind. This makes it change to pink from its yellow color.

Bronze Electrical Conductivity vs. Brass Electrical Conductivity

Copper can conduct electricity easily. Assuming both have an equivalent amount of copper by weight, their electrical conductivity will be the same.

However, since they have other elements in them, they tend to have poor electrical conductivity.

Bronze vs Brass: The Melting Point

Brass melts between 315°C and 1080 °C. Bronze melts between 809°C and 1030 °C. This is an important fact to know as they can fail when they attain their melting points.

When these metals melt, they can be cast into various shapes. In addition, take note of the mechanical behavior of both these metals if you are making casings.

Bronze Vs. Brass: Thermal Conductivity

Bronze conducts less heat than brass. This makes bronze suitable for making radiators. When you want to manufacture components that need high energy transfer rates, use brass.

Brass Vs. Bronze: Existing Alloy Grades

Alloys come about when you mix different elements to make these metals. The mixture makes them suitable for certain applications due to characteristic improvements. Some popular alloys of bronze include:

- Manganese bronze

- Phosphor bronze

- Silicon bronze

- Aluminum bronze

- Leaded bronze

- Tin bronze

On the other hand, brass alloys include the following:

- Red brass

- 464 brass

- 330 brass

- Yellow brass

- 360 brass

Bronze Hardness Vs. Brass Hardness

Hardness is a measure of how responsive the metal surface of brass and bronze is to dents, scratches, etc.

A Brinell hardness scale will rate and measure bronze hardness from 40 to 440. However, brass scores 55 to 73. This concludes that bronze is harder compared to brass.

Weight of Bronze Vs Weight of Brass

Both these metals weigh differently:

- Brass – 8400 and 8730 kg/cu.m density

- Bronze – it varies from 7400 to 8900 kg/cu.m.

Machinability Properties: Bronze Vs. Brass

This is the measure of how resistance a metal is to techniques like milling, stamping, etc. Machinability determines which machining process you can use on the metals.

When determining machinability, you will compare brass and bronze to a standard material whose rating is 100%. With brass and bronze, their rating is below 100%.

Brass C360 alloy has copper making it behave well when machining. In addition, shaping brass comes easy than bronze. This makes it suitable for making items like jewelry.

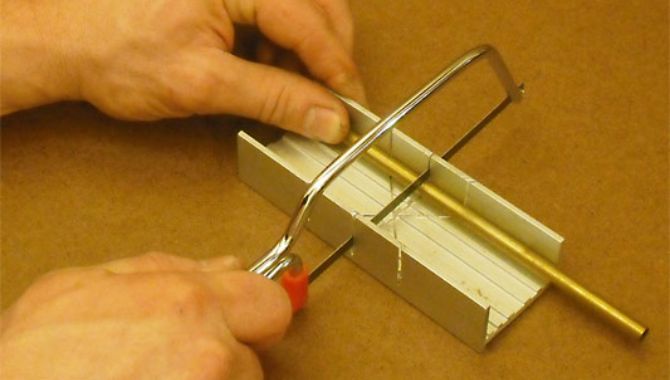

Ease of Forming Bronze vs. Brass

Brass is relatively a soft material. This makes brass easy to form by either cutting or shaping.

Cutting Brass

Cutting Brass

Mechanical Strength of Bronze Vs Brass

Here is how the different mechanical strength of these two compare:

| Type of Mechanical Strength | Bronze | Brass |

| Yield Strength | 69.0 to 800 MPa or 10,000 to 116,00 psi | 34.5 to 683 MPa or 5,000 to 99,100 psi |

| Ultimate Tensile Strength |

50 Ksi or 350 MPa (annealed)

92 Ksi or 635 Mpa (cold-rolled tempered) |

53 Ksi or 365 MPa (annealed)

88 Ksi or 607 MPa (cold-rolled tempered) |

| Shear Strength | 35000 psi – 47000 psi | 35000 psi – 48000 psi |

Welding Properties of Brass vs. Bronze

If brass has minimal zinc elements, welding will be easy. However, if it has lead constituents, welding will be difficult. If you have 20% or less amount zinc, welding is doable.

Also, if the zinc content surpasses 20%, it is fairly weldable. In addition, brass that is cast has minimal welding opportunities available.

You can fairly weld unleaded bronze alloys. However, it you subject them to stress, possibility of cracking is high. Moreover, when it comes to welding these metals, a shielded metal arc welding is a perfect choice.

Anti-Bacterial Property: Brass Vs. Bronze

Copper within brass and bronze is able to produce ion compounds that attack a variety of microorganisms. For this reason, they are conducive for making water filtration units and for sanitation.

In addition, the high manganese element in brass adds to its antibacterial property. This makes it suitable for making zippers, locks, etc.

Anti-biofouling property: Brass Vs. Bronze

Biofouling happens when marine elements like slime algae, barnacles, etc. stick on the surface of marine structures. The presence of copper can minimize macro-fouling levels. This property makes brass and bronze suitable for marine use due to their anti-biofouling characteristics.

Magnetic Properties of Bronze Vs Brass

The two metals are non-magnetic. This is because zinc and copper elements form non-magnetic compounds.

Brass Pipe

Brass Pipe

Quick FAQs

What is Better Bronze or Brass?

Brass and bronze have specific traits that make them better for different usages.

Between Bronze and Brass; Which one is More Expensive?

Be ready to spend more on bronze. Why? Because you will find more copper in bronze. Besides, copper is expensive than zinc.

How do you Differentiate Bronze from Brass?

Using color is a good way to differentiate these metals. Brass has a muted dull gold hue. Bronze exhibits a reddish color.

Does Bronze Break Easily?

Bronze is a hard material. Therefore, it is brittle and can fracture easily.

Does Brass and Bronze Rust?

No. they will not rust as they have miniscule iron content in them.

Relevant News