Titanium Vs. Aluminum – The Ultimate Comparison

Upload Time:

Feb 25, 2024

Both titanium and aluminum have silvery hues, and they find applications in many industries. They are popular engineering materials in the aerospace industry. But what properties do titanium and aluminum share? And, what makes aluminum different from titanium? Well, this guide compares everything you should know about titanium vs. aluminum:

Titanium Vs. Aluminum Extraction Process

Titanium Sheet Metal

Titanium Sheet Metal Aluminum Sheet Metal

Aluminum Sheet Metal

Both aluminum and titanium do not exist in pure forms. They are chemically extracted from their natural ores. Aluminum commonly exists as an oxide alongside iron oxide and silica in naturally occurring bauxite.

Extraction of alumina (aluminum oxide) from bauxite is via an electrolytic reduction method called the Bayer process. Another chemical process called the Hall-Heroult process extracts aluminum metal from alumina.

The titanium also exists naturally as an oxide in materials such as ilmenite and rutile. From here, you can extract titanium chemically.

The common reduction methods employed to obtain titanium metal are the Kroll process and the Hunter process.

Alloying Titanium Vs. Aluminum

Alloying refers to the bonding of metals with other metals or non-metals.

As a result, you get compounds with desired properties. Titanium and aluminum are some of the most alloyed metals.

Thanks to their impressive properties such as durability, strength, and lightweight.

Some elements you can alloy with titanium are aluminum, molybdenum iron, and vanadium.

Aluminum is also a popular alloying agent. You can combine aluminum with magnesium, copper, manganese, zinc, and silicon.

Physical Properties of Titanium Vs. Aluminum

Physical properties are integral when choosing titanium or aluminum for any application.

Corrosion Resistance

Corrosion resistance refers to a material’s ability to withstand deterioration induced by its interaction with substances in its surrounding. Titanium and aluminum exhibit great corrosion resistance quality.

In most cases, they form thin oxide layers that shield the substrate metal.

However, factors such as temperature and the strength of the corrosive agent influence the corrosion rate. Titanium has a higher melting point than aluminum. Therefore, it offers more corrosion resistance at higher temperatures.

The feature makes it a perfect choice for specialized applications such as the aerospace industry.

Conductivity

When evaluating conductivity, it is vital to consider thermal and electrical conductivity.

Aluminum Heat Exchanger Tubes

Aluminum Heat Exchanger Tubes

Electrical Conductivity

A material that allows electrons to flow through it stemming from a low resistance to such flow is an electrical conductor.

Both titanium and aluminum allow for electrical current transfer. However, aluminum has the least resistance compared to titanium.

While aluminum can conduct electrical signals to over 60% of copper’s capability, titanium’s conductivity is just about 3%.

Therefore, aluminum is a better alternative where electrical conductivity is a priority.

Thermal Conductivity

Titanium’s thermal conductivity is 17 W/m-K, while aluminum’s is 210 W/m-K. Therefore, aluminum is a better conductor than titanium.

A reason aluminum is popular in heat applications such as heatsinks and cookery appliances.

Melting Point

Titanium Tubes

Titanium Tubes

A metal’s melting point is critical before choosing any material for any application.

Titanium has a high melting point of over 1650 °C. On the other hand, aluminum’s melting point is about 600 °C.

Titanium’s high melting point makes it perfect for refractory applications. These are applications requiring high heat tolerance.

Density

Titanium density is 4500 kg/m3, while aluminum is about 2700 kg/m3.

This means, for the same volume, titanium has a larger mass than aluminum.

Therefore, aluminum finds use over titanium in applications that are weight sensitive. However, when evaluating strength-to-weight capability, titanium is a superior alternative.

Durability

Over time, materials are subjected to different conditions and can wear out. This requires maintenance and repair.

Consequently, durability is a function of:

- Strength

- Hardness

- Resistance to deteriorating

Both titanium and aluminum are highly durable.

Aluminum Vs. Titanium Mechanical Properties

Mechanical properties play an integral role in engineering metal parts and components. Choosing titanium or aluminum depends on various aspects we will discuss here.

Machinability and Formability

Transforming metals into products requires machining and forming. You will use fabrications processes such as:

- Cutting

- Bending

- Rolling

- Turning

- Milling

These processes inflict stress, and the tolerance of the material being worked on speaks to its ease of machinability and formability.

Aluminum and titanium can be machined and formed to very fine tolerances.

Consequently, other limiting factors, such as cost and wastage, come into play. As a result, favoring aluminum for its low cost and recyclability.

Bending Titanium Tube

Bending Titanium Tube

Strength of Titanium Vs. Aluminum

Yield Strength

Pure titanium can demonstrate yield strengths anywhere between 170 and 480 MPa, while aluminum is between 7 MPa and 11 MPa.

These values are moderately low and inconsiderable for applications with heavy loads. However, there are titanium and aluminum alloys with high yield strengths.

Tensile Strength

Titanium can tolerate over 1100 MPa in tensional forces, making it a better choice than aluminum’s 300 MPa. Alloying is one way to augment aluminum’s deficiency in this area.

Hardness

Pure unalloyed titanium has a Brinell’s hardness of 70 HB, which supersedes aluminum’s 15 HB. This makes titanium the go-to metal where hardness is desired. It is less susceptible to deformation from infractions.

Titanium interacts with atmospheric oxygen to form an oxide layer.

The layer offers the underlying metal surface buffer protection. However, you can fabricate aluminum alloys to achieve higher hardness levels than titanium.

Cost Factor in Both Titanium and Aluminum

Cost is an essential factor when discussing project materials. Titanium is an expensive metal due to its complex extraction and fabrication process.

Contrarily, extracting and fabricating aluminum is inexpensive.

This makes it the most widely available metal. It is highly affordable.

A reason aluminum is common in most applications.

Applications of Titanium Vs. Aluminum

In today’s industries, titanium and aluminum are used in many applications. Some common applications are.

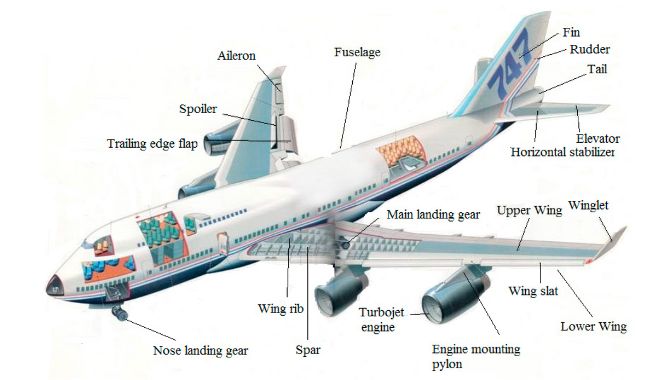

Aerospace Industry

Airplane Parts

Airplane Parts

Titanium and aluminum are used in the aerospace industry for their durability, strength, and lightweight. Titanium finds use in aircraft, such as engine components and parts of the landing system. Aluminum’s durability and low weight make it a perfect choice for aircraft frames and wing panels.

Building and Construction

Aluminum Building Structure

Aluminum Building Structure

The building and construction industry employs a wide material base to actualize structures such as bridges and skyscrapers.

Titanium finds widespread use in heating and power systems. Thanks to its low conductivity and tolerance to extreme temperatures.

On the other hand, aluminum finds common use as a finishing material in building construction. You find aluminum employed in roofing, as frames for doors and windows, and notably in interior design.

Automotive Industry

The automobile industry uses aluminum as body panels and engine parts such as radiator and transmission systems.

Titanium finds use in high-performance vehicles in motorsports due to its high cost.

Due to their durability and strength, other applications include connecting rods, exhaust systems, and engine valves.

Consumer Goods

Titanium

Sporting goods such as golf clubs and racquets employ titanium for its high strength-to-weight property. High-performance bicycles also employ titanium frames for the same reason. Other uses include: making spectacle frames, jewelry, firearms, and watch.

Titanium Bicycles

Titanium Bicycles

Aluminum

Inexpensive bicycles are made from aluminum frames. Also, packaging items such as cans for tinned food and beverages and foils are aluminum.

Unique Application

i. Titanium finds unique use in the medical industry for its biocompatibility. It is because the material is not toxic and poses no harm to tissues. You will find surgical instruments fashioned from titanium, implants, and prosthetics.

ii. Aluminum finds use in making kitchenware such as utensils, pans, and pots. Power transmission equipment such as motors, generators, and transformer parts and components employ aluminum.

Conclusion

As you can see, titanium and stainless steel are versatile materials for many applications. They are the perfect choice for specialized applications such as airplane parts and components.

A Dedasun, we help you get quality and reliable fabricated titanium and aluminum parts.

Relevant News