7 Types Rivets For Metal Sheets Assembly

Upload Time:

Feb 25, 2024

Rivets are fasteners that are used to connect parts in sheet metal assembly. In this article, you will find the most common seven types of rivets for sheet metal assembly. Therefore, before choosing your next rivets for the assembly process, read this guide.

1. Solid Rivets

You can use them in assembling sheet metals with ease and achieve strong parts.

Solid rivets are durable and easy to install.

Solid Rivets

Solid Rivets

The materials used in production are available in various colors and sizes you can choose from.

2. Tubular Rivets

They have hollow parts which are very strong. You can use tubular rivets in assembling aluminum and thin metals.

Tubular Rivets

Tubular Rivets

Tubular rivets are divided into two categories namely:

i. Full Tubular Rivets

Full tubular rivets have a deep drilled part with oval and flat head shapes. You can use this part to punch holes during sheet metal assembly.

Full Tubular Rivets

Full Tubular Rivets

ii. Semi-tubular Rivets

They possess a hole at their bottom. The hole will enable you to in force reduction during sheet metal assembly.

Semi Tubular Rivets

Semi Tubular Rivets

You can use them in light fixtures, electronics, ladders, HVAC ducts, and brakes.

3. Blind Rivets

They are very efficient whenever you cannot reach one side of a surface. For example, when you are dealing with hollow parts.

Blind Rivets

Blind Rivets

4. Flush Rivets

Flush rivets use both countersunk holes and heads. Flush rivets will give the outer surfaces of your parts a beautiful appearance. You can use them in airplanes to ensure a smooth flow of air.

Flush Rivet

Flush Rivet

5. Split Rivets

You will identify split rivets by the two legs at their bottom. Additionally, you will fold these legs back after the installation of split rivets.

Split Rivets

Split Rivets

You can use it on items like bicycle seats, leather, fabrics, and tin plates.

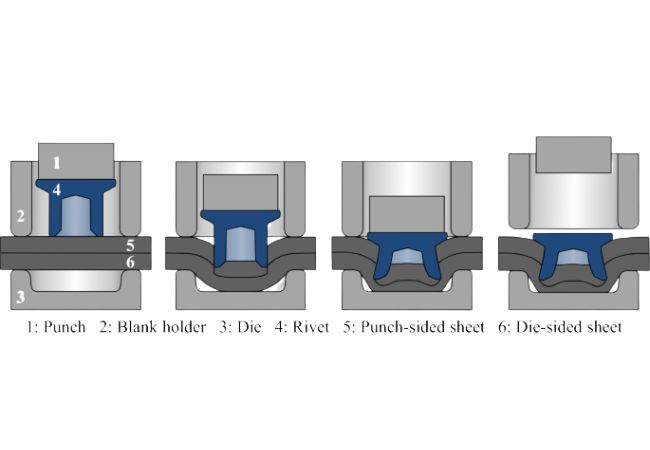

6. Self-Piercing Rivets

When using self-piercing rivets, you will not need to drill or punch holes. You will use the bevel drill at the end of the rivet and create a junction.

How Self-Piercing Rivets Work

How Self-Piercing Rivets Work

Your top part should have a wider hole as compared to the bottom part.

Its tail locks with sheet metal during assembly. This will form a button-like element in your sheet metal.

7. Friction Lock Rivets

You will install friction lock rivets by using sufficient force. You may use them in maintaining light aircraft.

Friction Lock Rivets

Friction Lock Rivets

Short FAQs On Rivets

Which Are The Best Materials For Making Rivets?

Some of the materials which you can use in making rivets include:

- Steel

- Stainless steel

- Brass

- Aluminum

- copper

What Are The Advantages Of Rivets For Sheet Metal Assembly?

Some of the advantages you will get from using rivets in sheet metal assembly include:

- Low material and operational costs

- You will obtain joints that are not visible.

- Rivets will ensure that your parts are easy to assemble and disassemble.

How Can You Remove Rivets

Some of the ways you can use to remove rivets include:

Option 1: Drill the Rivet Out Using a Dedicated Rivet Removal Tool.

- The tool has a drill bit and guide which you will use to position the bit over the rivet’s center.

Option 2: Drilling the Rivet Out Using Basic Tools

- You can use a plain drill bit to remove the rivets if they are only a few.

Option 3: Remove the Rivets Using Brute Force

- You will place the sharp end of a blunt-edged tool against the rivet and then hit the other end with a hammer.

Which Is The Strongest Rivet?

A solid rivet is the strongest rivet that you can use in sheet metal assembly.

Conclusion

Rivets play an important role in the sheet metal assembly process. With the correct rivet, you can secure all your sheet metal parts and components.

However, you should know the function and design of each rivet, before choosing it for any application.

Relevant News