Ultimate Guide to Injection Molding (2-2)

Upload Time:

Feb 25, 2024

To create critical components and ensure optimal performance, many manufacturers make use of injection molding. When businesses need high volumes of intricate parts, they turn to plastic injection molding. This process provides a high level of production while minimizing the cost per unit.

Injection Molding Design Guide

Apart from the tooling, material, and finishing selection, there is another integral parameter that affects the overall quality of the results. The design! The injection molding process comes with several limitations and the design needs to cater to them in order to ensure success.

Here are a few design elements that engineers carefully deal with while designing any part for injection molding.

Wall Thickness

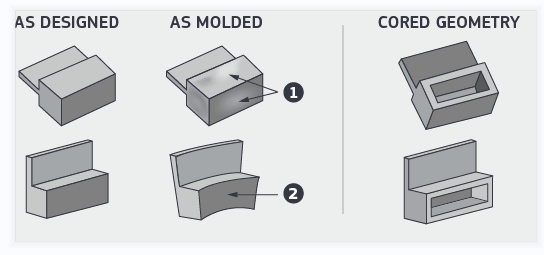

One of the most basic rules of injection molding design is to ensure that the wall thickness remains consistent throughout the part. Inconsistencies in the thickness can result in several issues down the line starting from mechanical defaults like stress concentration and micro-cracks that propagate with time.

Furthermore, inconsistencies in the wall thickness can also result in shrink variability, which can further create problems down the line. The most ideal scenario that experts recommend is to minimize any variability in the thickness and limit it to a maximum of 60% in the cases where it’s unavoidable.

Tolerances

Keeping the tolerances under control can ensure the perfect balance between cost, time, and complexity. Naturally, greater precision would lead to greater costs and complexities. Therefore, the design tolerances shouldn’t be more than what’s needed to ensure cost-effectiveness and efficiency without compromising on functionality.

Part Geometry

Building on to the last point, the geometry needs not to be unnecessarily complex for the injection molding process to deliver the best result. Naturally, complex designs have a trickle-down effect where they increase the cost and effort needed for tooling and then for the part production itself. Designs with a lot of cavities, cross-sectional variations, and other intricacies become harder to process and may need more resources, which can affect the viability of the product for the market or cause the business to lose its edge.

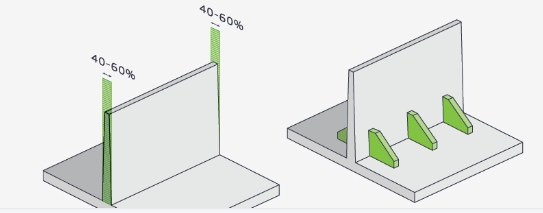

Draft

The draft is the inherent capability in the product design to facilitate ejection by tapering one side in the direction of the mold opening. The part’s geometry and design characteristics are the primary determinant of the ideal draft for the product. Generally, recommended minimum draft of 1 degree for excellent performance, but 2 degrees can work wonders and should be selected wherever feasible.

Radii

During the design phase, the product can have either sharp edges or smooth, rounded surfaces. However, smooth surfaces are almost always favorable because they allow for better mechanical characteristics and easier production. The liquified plastic flows relatively easier on rounded surfaces during production and the design also reduces the overall stress concentrations, something sharp edges are notorious for.

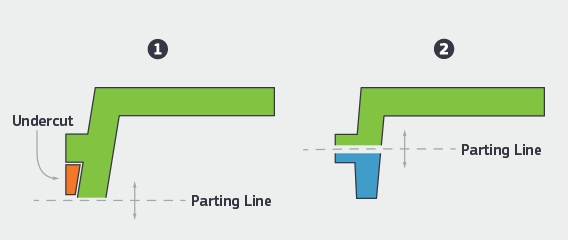

Undercuts

Undercuts are any feature or auxiliary that prevents the ejection of the part from a mold after cooling. While undesirable, some undercuts become necessary because of design considerations or the nature of the applications. Here are a few instances where undercuts become necessary for any injection molding design.

- Interlocking, snap-on/off features in any product

- Side holes or other cavities for buttons and other similar features

- Vertical threads or a barb fitting in the design

Since completely avoiding them is next to impossible, there are some ways to minimize the impact of undercuts on the process itself. For injection molding with undercuts, the best way to facilitate processing is to incorporate the part feature in such a way that it remains perpendicular to the drawn line. Doing so is one of the best solutions as it facilitates the ejection process without any compromise on the fundamental design and overall functionality of the part.

Gates

In the injection molding process, the gates act as a pathway for the molten plastic, and designers need to add them at the most precise location to ensure the best results. If the gate design is wrong, the part may become prone to many process-related injection molding defects including but not limited to flow lines, sink lines, weld lines, and many others.

Today, there are multiple types of gate designs like the edge, tunnel, and cashew gates that are commonly used for the best performance of the product. Here’s a brief table explaining the different types of gates along with their popular applications.

| Gate Type | Description |

| Edge Gates |

This simplest and most effective option is ideal for larger parts that are not too complex. These gates are common for parts with consistent thickness and isolate the shear stress. |

| Tunnel/Submarine Gate |

Tunnel gates are on the parting line which simplifies the post-processing by causing the gate to automatically eject. However, this choice is only for designs with small to medium cross-sectional areas. |

| Cashew Gate |

This is the perfect choice for applications where aesthetics play an integral role. Cashew gates are just like tunnel gates but have a greater curve, which hides the parting line below the exposed surface. Moreover, the limitations of cashew gates are the same as tunnel gates. |

| Direct Sprue Gate | Oldest and simplest gates that are hardly used across the industry. Sprue gates have high shear stress and are only viable for single cavity molds. |

| Diaphragm Gate |

These are an excellent choice for applications where a large cavity and even material flow are important. Diaphragm gates are a common choice for cylindrical and circular parts. However, they are not viable for other shapes. |

The gate ensures that no jetting or overheating happens during the process. When it comes to gate design, you must take great care to ensure consistency and performance at all times.

Ejector Pins

Depending on the complexity and intricacy of a design, the product might need a little more ‘push’ to separate from the mold. Ejector pins do exactly that but come with a severe drawback as well. As they apply force to eject the product, they are prone to leave unappealing marks on the part. This is an issue for all applications but becomes more severe for cases where the aesthetics are equally important as the functionality.

Nevertheless, it’s also true that the ejector pins are truly necessary. So, the best course of action is to simply accept the marks as a necessary evil. However, that doesn’t mean that they have to be so obvious that they become a dealbreaker. Luckily, the location of ejector pins is not pre-determined and designers can easily change them to ensure that any mark wouldn’t be at a very prominent location.

Common Industrial Applications of Injection Molding

Plastic injection molding is an excellent choice for manufacturing parts used in the aerospace, construction, IT, and food industries crucial to the applications at hand. To best understand how common it is, take one example of the food industry. Most of the packaging for hard products relies on injection molding to provide durable, yet flexible protection.

Now, let’s have a look at some of the most common industries where plastic injection molding is integral.

Automotive Parts

One of the largest industries in the world is the automotive industry. A lot of automobiles these days use plastic components be it the body kits, fenders, or even spoilers used for better aerodynamics.

All these parts are mostly produced using the plastic injection molding technique due to the accuracy and strength it provides.

Let’s take an example of a car’s body and multiple parts where plastic components improve the aerodynamic profile. Components made by this technique provide the characteristics that reduce drag force on the vehicle. That’s why many famous automobile companies use plastic injection molded components.

Medical Industry

When it comes to accuracy and sustainability, the medical industry is at the forefront. There are very stringent guidelines for manufacturing plastic parts in the medical field. For continued operations, manufacturers must abide by multiple production standards as there are lives at stake and any lapse can lead to a possible fatality.

Similar to automotive parts, medical parts require proper chemical properties and structural properties that can sustain higher temperatures for durability. Accuracy is key in this case because mostly the components are either for implants or for crucial surgical operations.

Plastic Injection Molding is an excellent manufacturing process because it provides increased strength, flexibility, durability, and easier modification. All these qualities are the key to carrying out crucial surgeries. Some common parts using this technique include surgical room prep equipment, supports for fractures, surgical equipment, and dentures.

Electronics

In micro-applications, plastic injection molding is widely used because it provides the required precision and quality of components in electronic items. Computers, laptops, and most small-scale electronics utilize the plastic injection molding technique for their smaller components.

Most of the notable components include motherboards, ram holders, casings of small computer parts that include RAM holders, and SSD encasements. The constricted requirements of dimensions are the primary reason why injection molding products are popular.

Aerospace Industry

When it comes to precision and structural strength, the field of aerospace has very strict guidelines. These days, most airplanes have their aerodynamic components produced through plastic injection molding. Seeing the boom in automotive, the aerospace industry has shown a lot of changing trends in following this technique for parts production.

The products in the industry using injection molding range from large to small. Most of the interior of seats and handles use ABS plastic, which has a certain grade that works with additive manufacturing techniques.

Retail

Coming to the presentability of the product of injection molding, then the most popular application of this technique is the parts used for display purposes.

The biggest reason why these parts use plastic injection molding is that it provides the aesthetics and the finishing integral for the application.

Household Items

The most common industry using plastic injection molding for manufacturing is household items. Looking around the house, anyone would surely find a lot of components in modern household items of plastic or resin material.

Common racks, window holders, handles and even holders for cutlery now use this technique. The core reasons why these components are being made through this technique are:

- Durability

- Finishing

- Quality

- Aesthetics

In a household, most people want their house to look nice and use plastic components that can ease their lives. Products made through this technique provide efficient durability and exceptional quality which is why it is a booming industry. Previously, metal components were being used especially for the kitchen which made things a bit difficult due to rust problems and the noise.

Ever since plastic products took charge, household items are now using this technique which just goes to show how common it is now. Exporters around the globe are now setting up major production plants that would solely produce such components and then supply them across the globe. China is an example, where a major chunk of the economy uses plastic products made through this technique.

FMCG Industry

The FMCG industry relies heavily on the injection molding technique. For packaging and coming up with aesthetic designs, FMCG companies use packaging components that are effective in coming up with innovative designs for packaging that are attractive to the customers as well. Apart from the aesthetics and finishing of the components, the FMCG industry also needs to abide by strict regulations for sanitization and safety.

Injection molding is quite capable of improving the overall quality of products without major issues that might be affecting the requirements of being BPA-free, FDA-certified, and other regulations. The most important regulation, in this case, is the non-toxic and GMA-safe regulation that plastic molding can deliver.

Construction Industry

Following a trend of making innovative products, many construction companies use products that assist their workers in maintaining the on-site progress through such components. Architects usually use protractors and geometry items made from injection molding. Here are a few reasons why these components are used:

- They provide cost-effectiveness as their mass production is cheaper than metal products

- Durability and flexibility of products that are important in multiple construction applications

- The low weight of parts and components

- Abiding by the quality standards of safety components

Some common products made from plastic injection molding utilized in construction include safety helmets, safety pads, design components, and various hand tools.

Major Factors Affecting the Cost of Injection Molding

Cost reduction is one of the most difficult parts of manufacturing and it can be troubling at times for a manufacturer. Optimizing the overhead cost and the manufacturing cost needs proper planning and balance of payments.

Let’s have a look at 8 crucial factors that can affect injection molding costs:

1 – Material Cost

The core reason why injection molding costs can increase is due to the material cost. At times, abiding by certain standards for a material requires the extra cost to keep the product of top quality. For example, regular production might not be as costly as production of FDA-approved material production, but it would cost more.

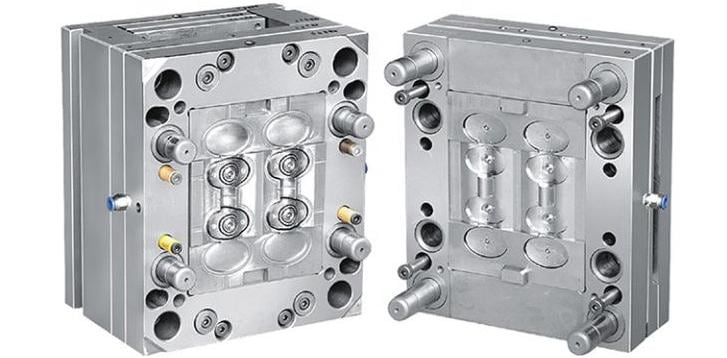

2 – Mold Cost

Sometimes, this cost is a one-time expenditure that can generate multiple products by re-utilizing the mold over and over again. However, this is not the case when it comes to innovative products such as customized mobile protectors and custom-made parts. The manufacturer would have to re-do the whole process of making the mold which would increase the cost.

3 – Labor Cost

This is a variable cost that varies according to the minimum wage and the amount of time the labor needs. Cost for labor may increase due to external factors such as inflation or an increase in electricity or other resources because then the wages would increase which would ultimately impact injection molding costs.

4 – Part Complexity

This primarily comes under the domain of mold cost as well because the more complex the part, the higher the cost because then mold would need additional resources. Furthermore, at times, a complex design might not yield a proper mold on the first attempt which may increase more cost.

5 – Mold Size

Molds also use specific material which is impervious to thermal stresses and can bear pressure at a higher temperature. An increase in the mold size requires additional material for manufacturing which culminates in an increase in injection molding cost.

6 – Production Volume

The production volume is one area where you can play around because it might increase or decrease the cost by making the right decisions. Mass production always lowers the overhead cost and thus increase in the production volume would increase profits and thus lower the costs and vice versa.

Here are a few tips on how to reduce injection molding costs:

- Increasing the production volume can yield better results when it comes to the overall cost and it would also generate more revenue.

- Regarding the complexity of the part, it is essential to review the design before signing up for the order to prevent any losses.

- Mold cost is usually on the rise so you must make sure that an older mold can be re-utilized or not.

- Topology Optimization is a technique that optimizes the design of products. Using this technique, the designer can easily identify the room for refining the design for manufacturing. Thereby, lowering the cost of molding.

Dedasun: The One-Stop Solution for Injection Molding Projects

Injection molding may sound like a relatively straightforward process but there is a lot that can go wrong. The tough competition in the current industry doesn’t leave a lot of room for errors and you to need to consistently remain on the lookout for opportunities to get an edge over your competitors.

For any business operating in the manufacturing sector, having the right processing partner is equally important as using the right materials. An experienced team can help gain true efficiency by optimizing the design for the best application and facilitating the process by using the right techniques and tools for finding efficiency and cost-effectiveness without compromising on the quality of the results.

The team at Dedasun has decades of experience doing exactly that! With global exposure, Dedasun is aware of any potential problems a project may have. Whether it’s a prototyping project with under 1000 cycles or a mid-level design with under 5000 cycles or a high-end industrial product with 100,000+ cycles. Dedasun is the way to go.

Furthermore, Dedasun also has one of the most stringent quality standards in the industry that ensure unmatched quality, consistency, and performance at the most competitive rates. With advanced facilities, integrated DfM systems, and a completely online design analysis process, Dedasun has no equal in the industry for injection molding and any other manufacturing need. It truly is a one-stop shop for everything manufacturing.

Relevant News