The Fillet Vs. Chamfer: A Detailed Comparison and Differences

Upload Time:

Feb 23, 2024

Manufacturer of various machines or tools, you’ll always need proper edges, especially between connecting surfaces. In that case, you’ll come across industry-standard options like bevels, fillets, chamfers, or rounds. There are various reasons for using these edge types; it could be to enhance the load-bearing strength of machines or metal parts, remove burrs or similar effects, or build machines or fabrications with excellent aesthetics and seamlessness.

Whatever your need for a smooth edge may be, before settling on which edge type to implement, you should understand their differences, applications, and mechanical advantages.

In this fillet vs chamfer comparison, we’ll examine the major differences between fillet and chamfer edges, including their costs and applications. So that by the end of this guide, you can make informed decisions when designing, buying, or building mechanical tools or devices. Continue reading to find out.

What Is a Fillet?

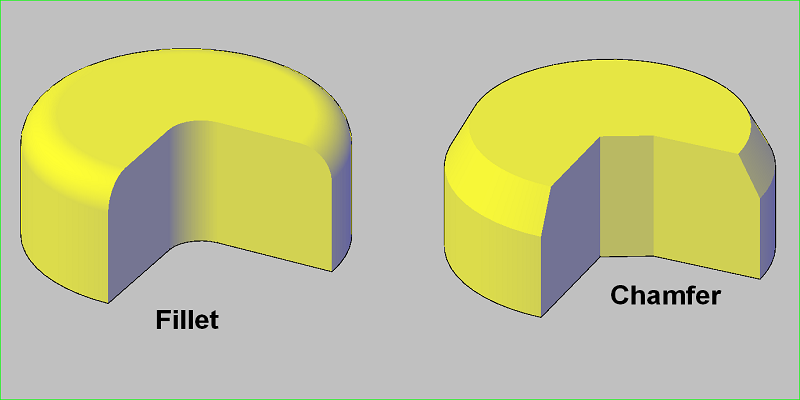

A fillet is a concave, rounded edge usually applied between connecting surfaces. To understand a fillet better, imagine a plane surface with an intersecting object; instead of a pointy or flat-tapered edge, the edge angle of the receiving surface is rounded according to the radius of the other intersecting object’s edge.

The rounded exterior or convex of the intersecting object, which blends into the fillet, is called a Round. Although the name fillet generally applies to both the interior and exterior parts of the edges—Round is less often used.

When you fillet two connecting surfaces, the tension in the joint is distributed over a larger surface area, which reduces stress in them, hence improving their load-bearing capacity and preventing the gradual wear and tear of the tensioned parts due to weight and friction—this is why fillet edges are preferably used to design technical parts of objects.

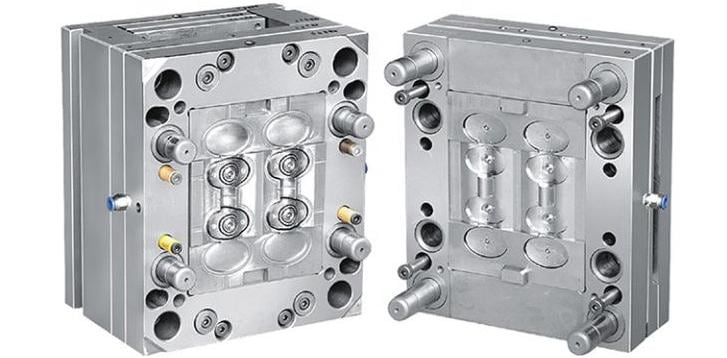

Fillets are used in metal and steel industries to improve the mechanical properties of load-bearing parts that are cast, welded, or molded. And in architecture for fillet vs chamfer 3D printing and designs. Real-world applications of fillets include the construction of buildings, bridges, or heavy machinery, where there is usually a need for high load-bearing capacity and accommodation for latent heat.

What Is a Chamfer?

A chamfer is an edge that is sloped at 45 degrees between connecting surfaces. When comparing bevel vs chamfer, there is hardly any difference. In fact, chamfers are often mistaken to be bevels. The difference, however, is that bevels are inclined to form a perfect cut or edge tapering or perpendicular to the face of the piece. Whereas chamfers are just small cuts of a pointy edge that slopes at 45 degrees or more depending on the complementing surface.

Chamfer is an alternative to fillet, used in improving the performance and aesthetics of mechanical parts. Although chamfers reduce stress like fillets, they don’t distribute it evenly as fillets, which makes them less suitable for high load-bearing objects or parts. Chamfers are applied in places where edges would normally meet at sharp angles, allowing connecting surfaces to balance finely and minimizing friction. Typical applications of chamfers include bolt edges, chamfer cutters, etc.

Why Use Fillet and Chamfer Edges

Filleting and chamfering can be used for various reasons. Typically, both are used in mechanical parts for safety reasons, for their aesthetic purposes, or as industry requirements. Here’s a further breakdown of why you should use fillet and chamfer edges.

For Safety Reasons

Fillets and chamfers are used to design the edges of mechanical parts for the following reasons:

- They prevent injuries from edge cuts: It’s normal for pointed edges to harm human skin. However, the exteriors of fillets and chamfers provide a cushion against pointed edges, making applied tools or machines safe to operate or handle.

- You can seamlessly join two edge surfaces: In manufacturing and machining, fillets and chamfers are great options to use to avoid wear and tear when assembling parts. They create a smooth joining effect for machine parts or tools.

- To decrease pressure: In heavy objects, the pressure is distributed to the base due to gravitational pull. Meanwhile, a fillet and chamfer edge helps to distribute the pressure equally at the base, reducing the risk of breaking or cracking.

Examples of where fillets and chamfers are applied for safety reasons include helmets, engine covers, sheet metal mailboxes, household utensils or equipment, electronic gadgets, toys, etc.

For Their Aesthetic Appeal

When fillets and chamfers are used to assemble or design the interior or exterior of object parts, they give a refined and elegant appearance or effect. Other aesthetic reasons may include:

- Harmony of parts: Fillets and chamfers create harmony in the assembling of object parts, which can enhance its performance and looks.

- Reducing the density of parts: Shaping the edge of an object with fillet and chamfer can reduce the stress concentration of that object without shading the stress resistance.

- Uniqueness of objects: Although chamfers might not be as appealing as fillets, they, however, stand out as the contrasting feature between two surfaces. They also add a bold definition to objects and surfaces.

- Speeding up production: In the production of parts, fillets and chamfers can ease the process and make it faster.

Some examples where the aesthetic nature of fillets and chamfers apply include

- Nameplate customization and the making of jewelry.

- Architectural designs such as the Burj Khalifa in Dubai

- Automobile designs

- And electronic products such as laptops, smartphones, and televisions.

As an Industry Requirement

Recent engineering industry standards encourage fillets and chamfers edges for the following reasons:

- Increasing the manufacturability of parts: Over the years, fillet has made manufacturing easier due to its machinability, especially when using Computer numerical control (CNC) machines. Also, chamfer is easier and faster to cut and smooth than straight edges.

- Reducing damage threats: Pointed edges have slope textures, which make them vulnerable to breakage and cracking. However, chamfers and fillets reduce the risk of these defects.

- To enhance parts experience: Chamfers and fillets improve the performance of machines and tools. For example, pipes use fillet curves to improve the flow of liquids while reducing wear and break due to friction.

Case studies that use chamfers and fillets are an Industry requirement include:

- In Aerospace: The aerodynamic structure of airplanes enhances fast movement against wind force. The finished edges of their landing gear, flight wings, blades, and fuselage use fillets and chamfers.

- In automobiles: In cars and bike engines, chamfer and fillet edges are used in parts like pistons and rings, pulleys, crankshaft, and engine blocks to reduce friction during combustion.

- In health and medicine: Fillets and chamfers are used in constructing first aid cabinet sheets and instruments like dissecting kits and syringes and examination and diagnosing instruments like stethoscopes and prosthetics.

- In electronics: Chamfers and fillets are used in assembling edges like circuit boards, diodes, heat sinks, and connectors in electronics.

Fillet Vs. Chamfer: The Core Differences

In this section, we’ll break down the core fillet vs. chamfer differences using criteria like their purposes, edges, cost, load bearing, stress concentration, etc.

1. Fillet Vs. Chamfer: Difference in Purpose

Fillets and chamfers have hardly any difference in purpose because they serve almost similar purposes. However, engineers may prefer fillets to chamfers for several reasons, like tensile strength and aesthetics. For instance, they reduce friction on sharp edges and distribute stress evenly across a surface edge.

In fact, fillets are more effective in reducing stress than chamfers, which makes them a preferred design in parts that require heavy loads. Also, fillets can withstand porosity better than chamfer edges. Conversely, while chamfers can lessen the stress on sharp edges, they are less suited for mechanical parts that use heavy loads.

The angular edges of chamfers make it easier to mate or assemble two or more parts. Also, due to their low-stress resistance, chamfers are used for surfaces that require little or no load. Manufacturing processes, like furniture for room dividers and counters, tooling, water tanks, mirror edging, etc., apply chamfers. They are also used in architectural design for concrete formwork and faded edges in machinery for cutting fine edge fitting, welding, and soldering of bolts and nuts.

2. Fillet Vs. Chamfer: Difference in Application

Here are various ways fillets and chamfers differ in application:

- Sheet fabrication: In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of different sheet metal materials. Examples are compartments, partitions, cabinets, and panels

- Construction: We use a fillet to assemble structural metallic materials, while chamfer is better suited for assembling beams, trusses, shafts, and columns

- Carpentry: We use fillets for furniture edges, such as table tops, bed edges, and chair edges and handles, due to their concave and convex structures. While chamfers are for joining two straight boards or wood panels, such as a wardrobe, tables, chairs, and cabinets.

- Piping and ductwork: Fillets are used more in HVAC industries for ductwork than Chamfer because of their thick layers and heat resistance. Also, both are used in plumbing industries to join pipes and pipe fittings

- Maintenance and repairs: Fillet and chamfer are frequently used to repair or support existing structures and equipment.

- Welding: Fillet and chamfer are both applicable in the welding of metals for construction, such as arc joints, L joints, T joints, lap joints, edge joints, and fillet and chamfered corner joints

- Manufacturing: Chamfer and fillets are both used in the manufacturing of different products such as machinery, plastics, tooling, and automobiles

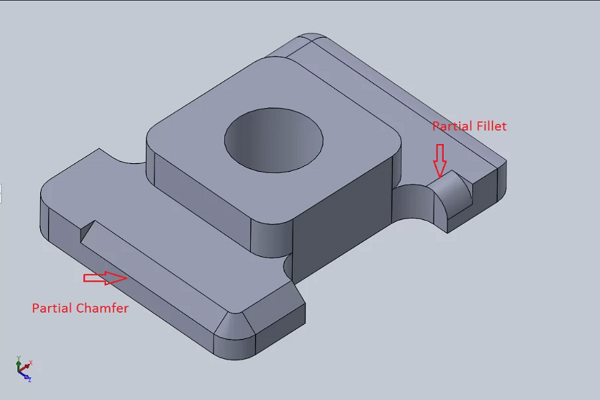

3. Fillet and Chamfer AutoCAD Designs and Fusion 360 Modeling

Chamfers and Fillet CAD (Computed Aided Designs) are shape tools in 2D and 3D architectural digital drawing on AutoCAD. You can initiate them using the fillet and chamfer AutoCAD commands. Chamfer AutoCAD operations involve joining two lines with a diagonal line at 45 degrees, while fillet operations join two lines with a curve or arc with smoothened edges.

Meanwhile, in Fusion 360 modeling, the choice between chamfer vs fillet depends on your purpose and budget. Chamfer is well-suited for applications involving higher ductility, lighter weight, less rust exposure, deep sitting, and appealing looks. Whereas fillet is best for areas that require strength, durability, weight, stress concentration, and balancing.

4. Fillet Vs. Chamfer: Difference in Edge Look

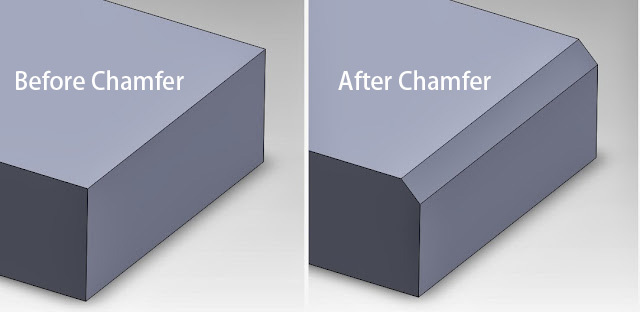

The edge looks of fillets and chamfer is one of the most distinguishing features of both designs. A fillet has an intuitively rounded or cornered edge. You can see instances in the table and cooking pot edges. While a chamfer has a beveled or angled edge—do not mistake chamfer for bevel though.

Filleted edges look more appealing and polished. They are preferred when designing internal surfaces because of the smoothness they give when they blend with other surfaces. They can also be suited for external surfaces because they cut out dangerous sharp edges.

In contrast, chamfered edges are typically angular at 45 and 60 degrees from the point where the two surfaces meet. Typically, chamfers at 45 degrees have a less sharp edge than chamfers at 60 degrees. Plus, chamfers at 45 degrees are more effective in reducing stress concentrations in materials, allowing them to sit well on the surface than those at 60 degrees.

Another distinct feature of chamfered edges over filleted edges is that when you chamfer the edges of a part, you have a specific base and a defined length. For this reason, chamfers are well-suited for surfaces with a linear shape. For example, in picture frames, the edges ease the stress concentration against the picture.

5. Fillet Vs. Chamfer: Difference in Cost

The cost of producing fillets is higher than chamfer due to the high demand and difficulty in producing them. Part of the reason for the high demand for fillets is due to its durability and safety provisions.

Generally, manufacturing a fillet requires a careful and time-consuming procedure—in most cases, the process requires several tools. For instance, producing a fillet requires an end mill that cuts the material parts carefully at a well-calculated angle, radius, and position of the object.

On the flip side, chamfer is cheaper to produce due to its straight edge. Normally, it is easier to cut a chamfer because it’s straight and precise. With simple calculations and markings, engineers can produce as many chamfers as possible in less time than fillets.

If you have a tight budget, your fillet vs chamfer conclusion should be influenced by the edge part you need and why. You may consult an engineer or technician for proper guidance.

Meanwhile, here are other common reasons for the difference in the cost of fillets and chamfers:

- High demand: The high demand for fillets contributes to their high cost compared to chamfers. Fillets are in high demand for several applications, such as furniture, machines, and architectural smooth finishing.

- The curved edge’s width: The wider the rounded surface or fillet radius, the costlier the object part. Chamfer is more cost-effective than fillet because it’s a more straightforward cut.

- Lower production quantity: Fillet parts are not as widely produced as chamfers, contributing to their higher price difference.

6. Fillet Vs. Chamfer: Difference in Load Bearing Tolerance and Stress Concentration

Based on the design, machine parts with fillets and rounds allow proper weight distribution. Hence, when carrying loads, the weight of the material rests comfortably and evenly distributed around the fillet, which reduces the stress. But it’s quite different from chamfer. Because of the sharp angular edges, chamfers are best suited for assembling or mating parts.

Chamfers offer little movements and can be great when you want two parts to stay put with the least motion. In general, it’s not ideal to choose chamfers for stress-reduction purposes as they can even be the source of stress at transition points between the chamfered object and the other part.

7. Fillet Vs. Chamfer: Difference in Edge Design Strength

Edge strength is an important factor in the chamfer vs. fillet debate as it determines the durability of the edges of mating parts. Smoothen, rounded edges reduce the likelihood of cracks and fractures in edges as there is no sharp angular point. As a result, fillet edges last longer than their chamfer counterparts, which are known for a lower life span, especially when fabricated with inferior alloys.

8. Fillet Vs. Chamfer: Difference in Safety

One of the major reasons for cutting an object into fine, smoothened edges is for protection against injury that may result from the sharp-edged nature of the object. Generally, it is safer when you fillet an edge than when you chamfer the edges because of the rounded cutting nature of fillets.

Fillets help to build smooth furniture edges and handles. They also find applications in various metallic parts, especially in places with high human traffic.

9. Fillet Vs. Chamfer: Difference in Machining Time

Fillets take time and are challenging to create. To achieve the curves, the machine—depending on the one you’re using—has to probably cut several times across the same surface. The more precision and excellence needed in the job, the more time it would take to achieve it.

On the contrary, chamfer requires just a straight cut at an angle of 45 degrees or any desirable angle. This is achieved by creating the printer pattern on the object that will be used to cut the material like a linear cut.

10. Fillet Vs. Chamfer: Difference in Coating

Fillets are best suited for coating and paint because of their curved nature and thick layer. This makes it have a uniform distribution during coat or painting. It also provides less stress resistance and concentration, making it preferable for protective coating to chamfer.

On the other hand, the sloppy nature of chamfer is a reason coatings and any form of paint would peel off faster. The sharp points, too, created in chamfered edges will gradually reduce the thickness of the coatings as objects or people press against them.

Choosing Between Chamfer and Fillet

Fillet and chamfer applications cut almost all through forms of technical and engineering constructions. While they comprise different sheets like metals, non-metals, plastics, bricks, and furniture, they are very useful to your day-to-day needs. Let’s compare their differences in the tables below and how to choose the right one.

| Fundamentals | Fillet | Chamfer |

| Stress concentration | Low-stress concentration | Higher stress concentration |

| Safety | Highly safer | Less safe |

| Part assembly | Difficult to assemble | Easy to assemble |

| Economy and cost | More expensive | Less expensive |

| Part aesthetics | More appealing look | Less appealing look |

| Machining efficiency | More performance | Less performance |

| Prevent rust | Yes | No |

| Manufacturing process | More difficult | Less difficult |

| Hole function | Poor fitting | High fitting |

When to Use Chamfer Vs. Fillet

Choosing between fillets and chamfers depends on factors like your current industrial needs and environmental considerations. Each edge type has its uniqueness and advantages. Fillets are known for their aesthetic, safety, stress resistance, fillet machining efficiency, and suitability for high humidity scenarios and corrosive elements.

Conversely, chamfered edges bring their lightweight nature and ability to withstand stress and extreme weather conditions. Additionally, it has advantages like cost-effectiveness, resistance to corrosion, and environmental sustainability.

When choosing an edge type, you must weigh the factors that hold the most significance for your specific project. That way, you can use the parts that best align with your objectives and priorities.

Saving Costs for Your Fillets and Chamfers

Every industrialist or engineer aims to solve problems with the least cost possible. To do this, you must answer some questions about your project. For instance:

- What is the purpose of chamfering or filleting the object?

- Are these fillet or chamfer edges necessary for the part to function?

- How cheap is adding these edges to the quantity I’m manufacturing?

- Do I have the budget for edge designs or fabrication?

- How can the load tolerance of the fillet or chamfer be checked? (note that the tighter the tolerance, the costlier the parts).

- What’s the easiest platform to design these surfaces, either chamfered or fillet corner?

- And lastly, where can you purchase fillet and chamfer parts at a good rate?

Notably, you can save money on fillet and chamfer by purchasing in bulk. If you need a large quantity of fillet or chamfered edge, you can choose a package with trusted manufacturers like KDM Fabrication. When you recycle your old or scrap parts, you can sell them to your supplier, and this will reduce waste and enable you to make more money.

If you are considering the best price for old fillets’ mechanical and chamfered edge materials and how to get the actual price from the fluctuating market,

- First, verify the current old parts price to be informed and know what to expect.

- Then, compare these prices at various recycling establishments within your area. Lastly, weigh them if possible and sell your scrap object in larger quantities rather than bit by bit.

Conclusion

In this fillet vs chamfered comparison, we examined the definition of chamfer and fillet, answering some of your questions, like “What does chamfered mean? What is the purpose of chamfering? And What is a fillet in engineering?” We also examined the core differences. You have also learned about the reason for their cost differences. By now, you should know the edge type best suited for your project.

Meanwhile, you would also need to get quality filleted or chamfered parts or materials from a metal fabrication company you can trust. Whether you are a manufacturer or constructor or need fillet edges and chamfered materials for aerospace, hospital, automotive, and industrial purposes, Dedasun has a team of engineers and welders working hand-in-hand to offer you the best products that suit your construction needs.

With decades of successful service deliveries and tons of certifications, including UL, NEMA, ISO, and REACH, you will surely get the best value for your money. Contact Dedasun today for personalized sheet metal bending, laser cutting, welding, or finishing solutions for your project.

Relevant News